What makes CVV power cables the top choice for low-voltage electrical systems? The answer lies in the super conductive copper core and dual PVC insulation layers – an optimized design for both power transmission and control.

As a low-voltage power cable, CVV not only meets the standards for residential projects but also serves as a specialized solution for industrial automation systems with control cables. This article will analyze in detail the construction, technical specifications, practical applications, and comparison with CXV cable to demonstrate why CVV is a comprehensive choice for all needs!

1. Overview of CVV power cable

According to the TCVN 6610-4/IEC 60227-4 standard, CVV low voltage power cable is a type of low voltage cable specially designed with copper conductor and two layers of PVC sheath, commonly used in power transmission and distribution systems with voltage levels of 300/500V and 0.6/1kV. The name CVV is formed from three characters, representing the structural characteristics and distinguishing it from other cable types:

C (abbreviation of Cu/Copper): Indicates the conductor is made of copper

First V: Represents the inner insulation layer made of PVC material

Second V: Indicates the outer sheath layer is also made of PVC material

In the low voltage electrical system, CVV cable plays an important role thanks to its outstanding advantages:

- High mechanical strength: The class 2 stranded conductor structure combined with two layers of PVC sheath helps the cable withstand good tensile and bending forces, with a test voltage up to 3.5kV

- Effective interference resistance: The double PVC sheath creates a shield to protect the signal from electromagnetic interference (EMI/RFI)

- Flexibility in installation: Suitable for underground, overhead or conduit applications according to IEC 60502-1 standard

- Fire and explosion safety: PVC material can self-extinguish when exposed to fire, meeting the TCVN 6612/IEC 60228 standard for fire safety

In addition to CVV cable, CV wire is also a popular type of power cable with a simple structure, commonly used in residential electrical systems.

To better understand the structure and application of PVC insulated copper cable, we will delve into each component of its structure.

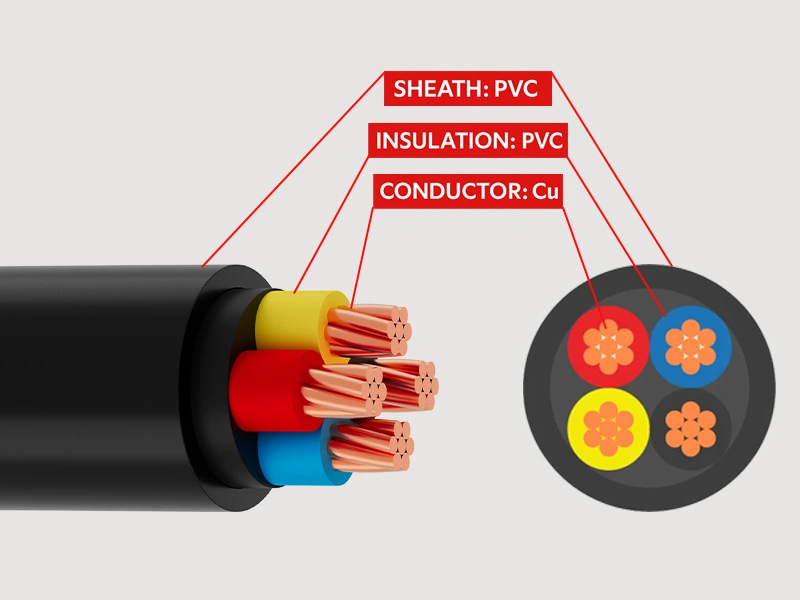

2. Detailed structure of CVV cable

CVV power cable is designed with a 3-layer structure, each layer having a distinct function to ensure effective power transmission and durability in use. From inside to outside, the cable structure includes:

1. Electrical conductor:

- Made by pure copper

- Class 2 stranded structure of multiple annealed copper wires

- Diverse cross-sections from 1.5mm² to 300mm²

2. Main PVC insulation layer:

- Made of PVC material

- Standard thickness according to TCVN 6610-4

- Good heat and chemical resistance

3. Outer PVC sheath:

- PVC insulation sheath layer

- UV and weather resistance

- Self-extinguishing property when burning

To further understand the operating capabilities of CVV low voltage power cable, we will examine its detailed technical specifications.

3. Detailed technical specifications of CVV cable

| Specification | Value | Applied standard |

|---|---|---|

| Test voltage | 2kV/5 minutes or 3.5 kV/5 minutes | TCVN 6610-4 |

| Rated voltage | 300/500V or 0.6/1 kV | IEC 60502-1 |

| Operating temperature | 70°C (continuous) | AS/NZS 5000.1 |

| Short-circuit temperature | 140°C (≤300mm²) 160°C (>300mm²) | TCVN 6612 |

These technical specifications play a decisive role in the selection and use of CVV copper cable:

- 3.5 kV test voltage ensures high safety during operation

- 70°C operating temperature suitable for most environmental conditions

- Ability to withstand high short-circuit temperature helps protect the system in case of failure.

Next, we will learn about the practical applications of PVC-insulated copper cable in specific projects.

4. Practical applications of CVV cable

To better illustrate the diverse applications of CU/PVC/PVC cable, we will analyze two real projects that have been successfully deployed in Vietnam, as cited from the National Bidding Network System.

4.1. Application 1: Terminal T3 – Tan Son Nhat Airport

Project name: Supply of Indoor Mobile Broadcasting System (IBS) for Terminal T3 – Tan Son Nhat Airport

Investor: BRANCH OF VIETNAM POSTS AND TELECOMMUNICATIONS GROUP – HO CHI MINH CITY TELECOMMUNICATIONS

Information codes:

TBMT code: IB2400608775

KHLCNT code: PL2400256694

Technical specifications:

Material name: CVV/CXV 2×6 mm² electric cable

Installation length: 780m

Application: The Indoor Mobile Broadcasting System (IBS) requires CVV cable with high stability and RFI/EMI interference resistance.

4.1.2 Application 2: Hoai Nhon Town, Binh Dinh

Project name: Maintenance of public lighting system, decorative lights, traffic lights and repair of electronic boards in Hoai Nhon town in 2025

Investor: HOAI NHON TOWN URBAN ORDER MANAGEMENT TEAM

Information codes:

TBMT number: IB2500030308

KHLCNT code: PL2500014310

Technical specifications:

Material name: CVV 4×1.5mm² cable

Installation length: 150m

Application: The public lighting system and traffic lights require CVV cable with high durability and good heat resistance.

Note: The two applications above are taken from the National Bidding Network System of the Ministry of Planning and Investment (https://muasamcong.mpi.gov.vn/web/guest/home), ensuring accuracy and reliability.

4.1.3 Application analysis

From the two case studies above, it can be seen that CVV low-voltage electric cable is widely applied in:

Power transmission and distribution systems for large-scale projects

Projects that require high stability and durability

Fixed installation in many different environmental conditions

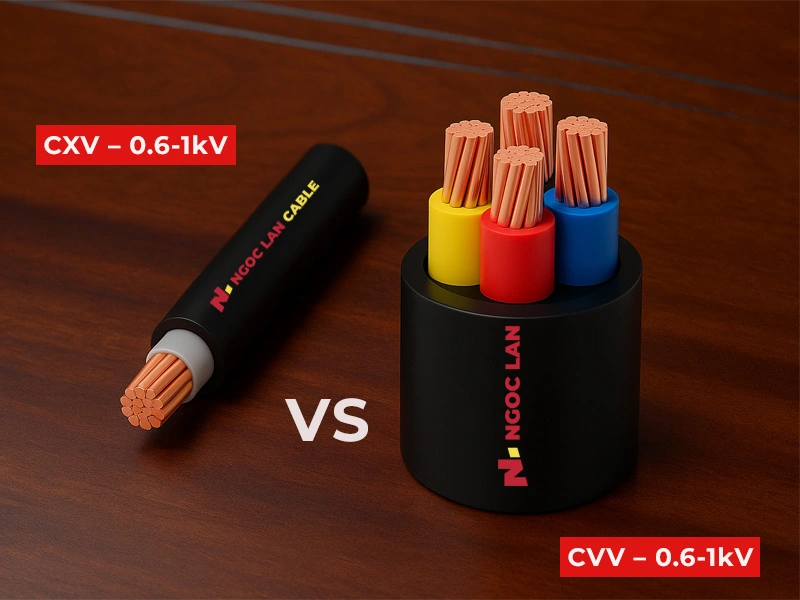

5. How CVV and CXV wires differ

| Criteria | CVV cable | CXV cable |

|---|---|---|

| Insulating material | PVC (Polyvinyl Chloride) | XLPE (Cross-linked Polyethylene) |

| Operating temperature | 70°C | 90°C |

| Main application | Civil and industrial projects | Heavy industry, manufacturing plants |

| Cost | More economical | Higher due to XLPE technology |

The main difference between CVV cable and CXV cable lies in the insulating material used. While CVV cable uses PVC material, CXV cable uses higher-grade XLPE technology, providing heat resistance up to 90°C, more suitable for heavy industrial applications. This leads to unique advantages for each type:

– CVV cable is suitable for civil and commercial projects thanks to its reasonable cost and easy installation

– CXV cable is suitable for industrial environments with high temperatures and more stringent technical requirements

Practical example: The installation cost of CVV copper cable for a 100m² house is usually 20-30% lower than using CXV cable of the same cross-section.

After clearly understanding the difference between these two popular types of cables, we will analyze in detail the electric cable market in general and PVC/PVC copper cable in particular, to have an overview of development trends and usage demand in the coming time.

6. Market analysis

To have an overview of the development prospects of CVV low voltage electric cable, we will analyze two main aspects: current market share through statistics and emerging trends in the industry.

6.1. Market share table

Based on data from the Ho Chi Minh City Mechanical and Electrical Enterprises Association (HAMEE), the wire and cable market is growing strongly, especially in the CVV cable segment:

| Market segment | Development characteristics | Influencing factors |

|---|---|---|

| Industrial projects | Strong growth | – Investment in renewable energy – Development of new industrial infrastructure |

| Public infrastructure | Development according to planning | – National power planning – Urbanization projects |

| Civil projects | Steady growth | – Housing construction demand – Electrical system renovation |

When looking at the development of the above market segments, we can see the growth potential of the industry. This leads to many notable new trends in product improvement and development.

6.2. New trends

The CVV electric cable market is witnessing some major development trends:

Environmentally friendly PVC materials:

- Increase the rate of recycled PVC usage

- Develop green manufacturing technology

Integrate sustainable building standards:

- Meet LOTUS certification requirements

- Optimize energy efficiency

Improve product quality:

- Apply new international standards

- Improve production processes

With advantages in flexibility, high durability and ability to withstand harsh environments, CVV cable is forecast to continue to play an important role in the development of Vietnam's electricity industry.

Next, we will learn about some frequently asked questions about CVV electric cable to have more useful information for product selection and use.

7. FAQs about CVV electric cable

“Is CVV cable suitable for harsh environments?”

Yes, CVV cable can operate stably in many harsh environmental conditions thanks to:

– PVC sheath has good moisture and UV resistance

– Can withstand operating temperatures up to 70°C

– High resistance to mechanical impacts

“What is the function of the PVC insulation layer?”

The PVC insulation layer plays an important role in:

– Electrically insulating the conductor and the environment

– Protecting the cable from chemical impacts

– Ensuring safety when operating at a test voltage of 2kV or 3.5kV

8. Conclusion

Through the above analysis, you have seen the important role of CVV electric cable in modern electrical systems. Let's summarize the main points about this product:

- 3-layer structure with copper conductor and PVC sheath ensures high durability

- Meets stringent standards such as TCVN 6610-4 and IEC 60502-1

- Suitable for many applications from civil to industrial projects

These factors not only highlight the important role of CVV electric cable in the electricity industry but also demonstrate Ngoc Lan Cable commitment to providing CVV cable solutions that fully meet all necessary technical standards, ensuring safety and optimal performance for all installation needs.

To learn more about how to use the CVV cable or receive detailed technical advice, you can refer to professional documents on the website or contact us through our support channels.

VN

VN