Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

Did you know that those seemingly small electrical wires are actually crucial "assistants" that enable electrical devices to operate and bring convenience to our daily lives? However, not everyone fully understands how to select and use electrical wires safely and properly. This article will provide you with a comprehensive look at building wire, appropriate selection methods, and installation guidance for everyone from electricians and electrical engineering students to non-technical individuals.

Currently, building wire types are manufactured according to Vietnamese and international standards such as IEC 60228/ TCVN 6612; IEC 60227/ TCVN 6610; IEC 60227-3/TCVN 6610-3...

Flexible single wire (VCm)

Flexible single wire has a conductor made of multiple soft copper strands of the same diameter (0.15 - 0.61 mm), twisted together. The exterior is covered with PVC insulation.

Rigid single wire (VC, VA)

Rigid single wire has a conductor made of copper or aluminum, with an outer jacket made of PVC. Notably, aluminum conductors must have a nominal cross-section >= 3 mm²

Twisted single wire (CV, AV)

Twisted single wire has a conductor consisting of copper or aluminum strands of the same diameter twisted concentrically into 1 or multiple layers depending on usage requirements. The outer jacket is insulated with PVC or XLPE

Flat flexible twin wire (VCmd)

Flat flexible twin wire is a type of building wire consisting of two flexible conductors, each conductor made from multiple small copper strands braided together, making the wire flexible and easy to bend. These two conductors are PVC insulated, running parallel and spaced according to standard specifications.

Oval flexible twin wire (VCmo)

Oval flexible twin wire consists of two flexible conductors, each made from multiple small copper strands braided together and covered with a PVC insulation layer. After individual insulation, the two conductors are placed parallel and jointly covered by an outer PVC jacket in an oval shape.

Round flexible twin wire (VCmt)

Round flexible twin wire has a similar structure to oval flexible twin wire but with a round outer PVC jacket instead of an oval one.

Step 1: Determine usage requirements

Calculate the power rating of each electrical device requiring power supply, sum up for total system power. Survey installation conditions to select appropriate wire (outdoor, underground...).

Step 2: Calculate wire cross-section

Using the calculated power and wire length, use formulas or specification tables to select necessary wire cross-section. Larger cross-section means higher load capacity.

Approximate formula for copper wire:

S = (ρ * P * L * cosφ) / (γ * V)

Where:

S: Wire cross-section (mm²)

ρ: Resistivity (Ω.mm²/m)

P: Power (W)

L: Length (m)

V: Voltage (V)

cosφ: Power factor

γ: Conductivity coefficient

Step 3: Select material and wire structure

Based on cross-section and environmental conditions, choose wire type with appropriate characteristics like good conductivity, heat resistance, moisture resistance... as analyzed above.

Step 4: Check technical specifications and standards

Compare selected wire's technical specifications with actual requirements like rated current, voltage endurance, TCVN standards, IEC... This helps limit risks of purchasing low-quality wire.

Step 5: Choose reputable brands

Prioritize famous wire brands with clear quality certifications. Avoid unbranded products or counterfeit, poor quality wires that pose many risks.

Or if you lack experience in selecting standard wire, you should consult experts or reputable distributors. They will help advise on the most suitable wire type for your needs and budget.

1. Overview of building wire

1.1 What is building wire?

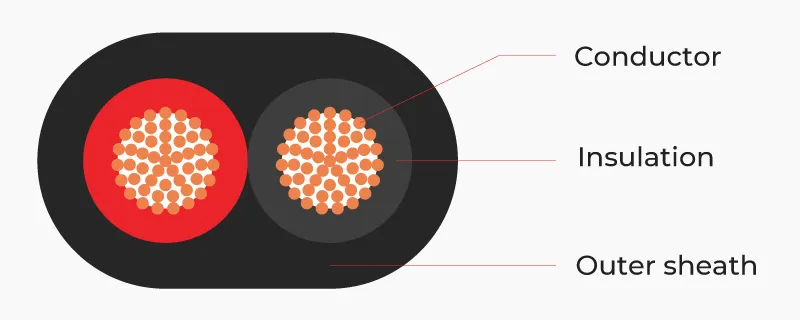

Building wire (also known as household electrical wire) is a type of electrical wire used to transmit electrical power from the supply source to electrical devices in residential buildings and civil construction projects.1.2 Structure

Building wire consists of 3 main layers:-

- Conductor core: typically made of copper or aluminum, responsible for conducting electrical current.

- Insulation layer: covers the conductor core, usually made of PVC (Polyvinyl chloride) or XLPE (Cross-Linked polyethylene). This layer prevents electrical current from contacting the external environment, avoiding electrical leakage.

- Protective jacket: the outermost layer, made from PVC or XLPE, helps protect the conductor core and insulation layer from environmental impacts.

1.3 Technical characteristics and applicable standards

Key technical specifications of building wire to note:-

- Rated voltage: thường là 300/500V, 450/750V or 0.6/1kV

- 50Hz test voltage for 5 minutes:

- Insulation thickness ≤ 0.6mm: 1.5 kV

- Insulation thickness > 0.6mm: 2.0 kV

- Max. conductor temperature in normal operation: 70°C (PVC) or 90°C (XLPE)

- Max. conductor temperature in short-circuit for 5s max duration: 160°C (PVC) or 250°C (XLPE)

Currently, building wire types are manufactured according to Vietnamese and international standards such as IEC 60228/ TCVN 6612; IEC 60227/ TCVN 6610; IEC 60227-3/TCVN 6610-3...

2. Types of building wire

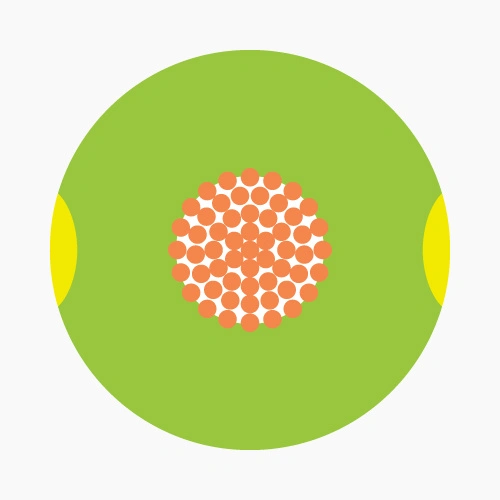

Building wire is classified into several types with different structures:Flexible single wire (VCm)

Flexible single wire has a conductor made of multiple soft copper strands of the same diameter (0.15 - 0.61 mm), twisted together. The exterior is covered with PVC insulation.

Rigid single wire (VC, VA)

Rigid single wire has a conductor made of copper or aluminum, with an outer jacket made of PVC. Notably, aluminum conductors must have a nominal cross-section >= 3 mm²

Twisted single wire (CV, AV)

Twisted single wire has a conductor consisting of copper or aluminum strands of the same diameter twisted concentrically into 1 or multiple layers depending on usage requirements. The outer jacket is insulated with PVC or XLPE

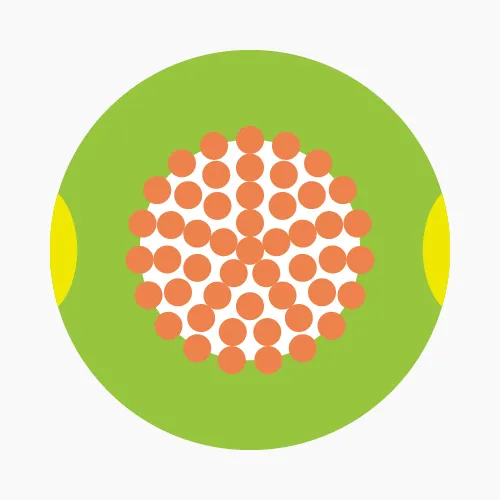

Flat flexible twin wire (VCmd)

Flat flexible twin wire is a type of building wire consisting of two flexible conductors, each conductor made from multiple small copper strands braided together, making the wire flexible and easy to bend. These two conductors are PVC insulated, running parallel and spaced according to standard specifications.

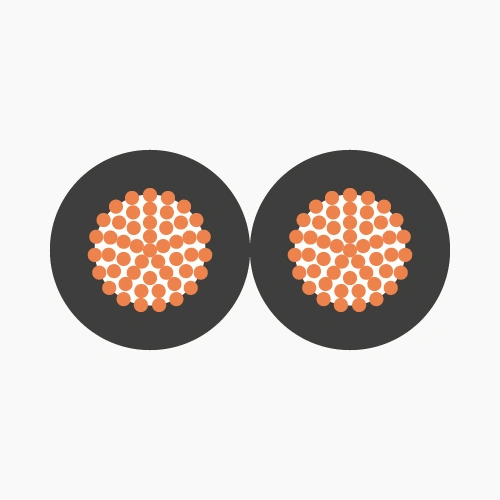

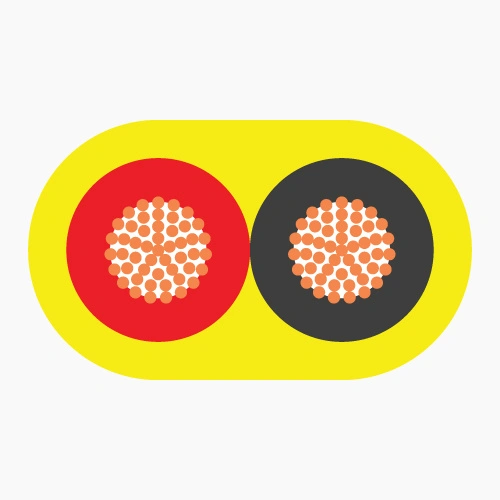

Oval flexible twin wire (VCmo)

Oval flexible twin wire consists of two flexible conductors, each made from multiple small copper strands braided together and covered with a PVC insulation layer. After individual insulation, the two conductors are placed parallel and jointly covered by an outer PVC jacket in an oval shape.

Round flexible twin wire (VCmt)

Round flexible twin wire has a similar structure to oval flexible twin wire but with a round outer PVC jacket instead of an oval one.

3. Applications of building wire

Building wire is integral to modern living. With diverse applications, electrical wires are present in most systems from basic to complex:-

- Powers household lighting systems including ceiling lights, wall lights, decorative lights, LED lights...

- Supplies power to essential kitchen appliances like refrigerators, electric stoves, washing machines as well as entertainment devices like TVs, computers, speakers, and personal care appliances...

- Installed within walls, connecting to electrical outlets to supply power throughout the home, enabling convenient use of electrical devices.

- Used for fixed electrical systems like water heaters, air conditioners, water pumps, and gate electrical systems. Additionally, they have more specialized applications like underfloor heating systems, automatic irrigation systems, and residential solar power systems.

4. Advantages and disadvantages of building wire types

Each material and wire structure has its own strengths and weaknesses. Let's examine the detailed comparison table below:-

- When comparing copper and aluminum wire, copper excels in electrical conductivity, heat resistance and lifespan. However, aluminum is lighter and cheaper, making it commonly used for power cables and light-load applications.

- Single and stranded wires differ mainly in structure. Single wire is more durable, suitable for fixed installation. Conversely, stranded wire offers more flexibility, working well for conduits and mobile devices.

- Between PVC and XLPE, PVC is an economical choice for standard equipment. XLPE performs better in terms of heat resistance and fire safety, making it trusted for high-requirement systems.

5. Guide to selecting appropriate building wire

Choosing the right building wire isn't simple without careful preparation. Here are the necessary steps to ensure the wire meets requirements:Step 1: Determine usage requirements

Calculate the power rating of each electrical device requiring power supply, sum up for total system power. Survey installation conditions to select appropriate wire (outdoor, underground...).

Step 2: Calculate wire cross-section

Using the calculated power and wire length, use formulas or specification tables to select necessary wire cross-section. Larger cross-section means higher load capacity.

Approximate formula for copper wire:

S = (ρ * P * L * cosφ) / (γ * V)

Where:

S: Wire cross-section (mm²)

ρ: Resistivity (Ω.mm²/m)

P: Power (W)

L: Length (m)

V: Voltage (V)

cosφ: Power factor

γ: Conductivity coefficient

Step 3: Select material and wire structure

Based on cross-section and environmental conditions, choose wire type with appropriate characteristics like good conductivity, heat resistance, moisture resistance... as analyzed above.

Step 4: Check technical specifications and standards

Compare selected wire's technical specifications with actual requirements like rated current, voltage endurance, TCVN standards, IEC... This helps limit risks of purchasing low-quality wire.

Step 5: Choose reputable brands

Prioritize famous wire brands with clear quality certifications. Avoid unbranded products or counterfeit, poor quality wires that pose many risks.

Or if you lack experience in selecting standard wire, you should consult experts or reputable distributors. They will help advise on the most suitable wire type for your needs and budget.

6. Factors affecting building wire prices

Electrical wire isn't an inexpensive item, so you should understand the factors that determine its price:-

- Wire material: Copper is always more expensive than aluminum. XLPE rubber and silicone are also more expensive than PVC.

- Wire dimensions: Larger cross-sections and longer lengths mean higher prices.

- Brand: Wire from major, reputable manufacturers typically costs more.

- Manufacturing technology: Wire produced using advanced, modern technology will be more expensive than mass-produced wire.

- Distribution channel: Wire prices will vary depending on retail vs wholesale sellers, shipping costs...

7. Safety measures for installation and usage

Even with high-quality wire selection, improper installation and usage can easily cause dangerous incidents. Here are some safety considerations:-

- Only install electrical wire if you have electrical expertise or hire a skilled electrician.

- Always turn off the main circuit breaker before repairs or installation. Use a voltage tester to verify wire is no longer live.

- Keep wire away from water, corrosive substances, sharp objects. Immediately cover exposed wire with electrical tape.

- Install wire neatly, away from heat sources. Don't let wire bear excessive tension or become twisted.

- Use automatic switches and fuses for overload protection. Regularly check for electrical leakage using RCD.

- Immediately replace old or damaged wire sections. Don't make temporary repairs or splice wires.

- Keep children and animals away from electrical wires.

- If there are abnormal signs like hot wires, burning smell, switch shock... disconnect power and repair immediately.

VN

VN