How many parts does an electric cable structure consist of is a fundamental question that every electrical engineer, construction contractor, and industry specialist needs to master. Understanding the structure and function of each cable component not only helps optimize transmission efficiency but also ensures absolute electrical safety in all systems, from low voltage cables to medium voltage cables.

Basic structure according to technical standards:

- According to TCVN standards and international IEC standards, standard cable construction is built from 3 core components

- Each part undertakes a specialized role in the electrical conduction and protection process

- Specialized cable types also add many auxiliary layers to meet high technical requirements in harsh industrial environments

This article will analyze in detail each construction layer and the relationship between materials and operating performance, while providing guidance on appropriate selection for each specific application. With deep expertise in the field of electric cable manufacturing, Ngoc Lan Cable is committed to providing the most accurate professional knowledge about the physical nature and operating principles of each component.

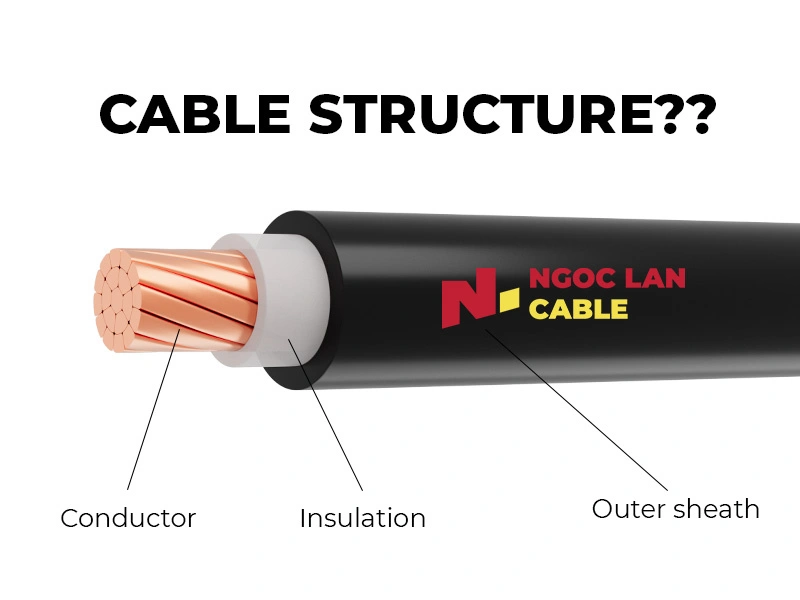

1. Standard electric cable structure consists of 3 main parts

According to TCVN standards and international standards such as IEC, basic electric cable construction is built from 3 main components, each part having separate roles and functions in the electrical transmission system.

These three components include:

- Conductor

- Insulation

- Sheath

This structure is designed to optimize transmission efficiency and ensure operational safety for all applications from residential to industrial.

1.1. Part 1: Conductor – The current transmission component

The conductor is the central and most important component, whose main function is to transmit electric current from the source to the consumption load. This is the “pathway” where electrons move to perform the electrical conduction process effectively.

In terms of structure, the conductor can be concentric stranded (multiple small wires twisted together) or concentric stranded circular compacted. The number of wires commonly used is 7, 19, 37, or 61 wires depending on the cross-sectional area and specific application requirements.

The conductor material is usually copper (Cu) or aluminum (Al), widely used due to their low resistivity and good electrical conductivity. Copper is preferred due to its high electrical conductivity (resistivity at 20ºC only 0.017241 Ω.mm²/m), good mechanical strength, and superior corrosion resistance.

| Comparison criteria | Copper conductor (Cu) | Aluminum conductor (Al) |

|---|---|---|

| Resistivity | 0.017241 Ω.mm²/m | 0.0283 Ω.mm²/m |

| Specific gravity | 8.96 g/cm³ | 2.70 g/cm³ |

| Tensile strength | High (220-250 MPa) | Medium (70-120 MPa) |

| Cost | Higher | 30-40% lower |

1.2. Part 2: Insulation – Core protection system

The insulation layer surrounds the conductor, playing the role of electrical isolation between the conductor and the surrounding environment. It also functions to isolate between conductors in multi-core cables and separate them from grounded objects, ensuring absolute safety for the system.

The insulation layer is made from PVC (Polyvinyl Chloride) and XLPE (Cross-linked Polyethylene), which are the 2 most common types. PVC insulation has low cost and easy processing but only withstands temperatures up to 70°C. In contrast, XLPE insulation has higher heat resistance (90°C) and better mechanical strength, although the cost is usually higher than PVC.

Choosing good insulation material directly determines the lifespan and safety of the electric cable, especially important in industrial applications and high voltage transmission.

1.3. Part 3: Sheath – External mechanical protection layer

The sheath is the outermost layer, responsible for enclosing all cores and providing mechanical and chemical protection for the entire internal structure.

The main function of the sheath is to resist environmental impacts such as impact, moisture, chemicals, and UV rays, ensuring long-term durability for the electric cable.

Unlike the insulation layer which focuses on insulation properties, the sheath primarily undertakes the role of mechanical protection, having high mechanical strength and good aging resistance in harsh environments. Materials commonly used are standard PVC or plastic materials used for fire-resistant cables such as LSZH, FR-PVC (Fire Resistant PVC).

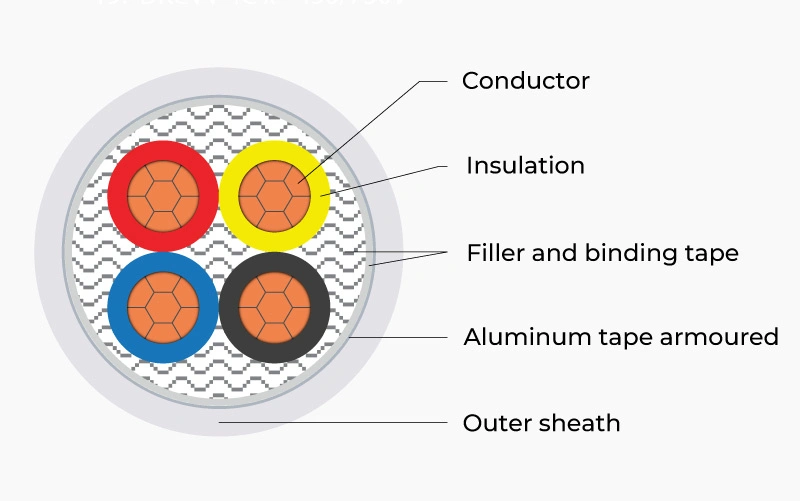

2. Common auxiliary components in specialized electric cable construction

Besides the 3 main components analyzed above, specialized electric cable types are often supplemented with many auxiliary layers to meet high technical requirements in harsh industrial environments.

Understanding the role of each auxiliary component will help you choose the right cable type for each specific application. This is especially important when working with projects requiring specialized electric cables for industry or systems with specific operating conditions.

2.1. Filler and binding tape – Cable shaping components

Filler and binding tape are 2 components that play an important role in shaping and stabilizing the structure of multi-core electric cables. The filler is placed in the gaps between conductor cores to make the cable bundle more circular. The binding tape has the function of securing the core bundle and filler strands, preventing the phenomenon of core position displacement when the cable is bent.

Commonly used materials:

- Filler materials are usually in round or flat fiber form such as polypropylene fiber (PP Yarn fiber), PVC fiber, synthetic fiber with non-conductive properties.

- Binding tape is usually Mylar tape, PE tape (Polyester film), PPF (Polyphenol formaldehyde/Polypropylene), PET (Polyethylene Terephthalate).

These materials must be selected to be compatible with the cable's operating temperature and insulation material.

Technical functions:

- Maintain uniform round shape of the cable during manufacturing and construction

- Minimize mechanical stress effects on individual conductor cores

- Improve flexibility and bending durability of the entire electric cable

Especially for multi-core control cables, the filler also helps separate different core groups, minimize cross electromagnetic interference, and ensure stable signal transmission quality.

2.2. Separation sheath – Protective barrier membrane

The separation layer is a material layer placed between different components in the cable, usually located between the conductor core group (with insulation) and the armor protection layer (or metallic screen). This component acts as a physical “barrier” preventing harmful interaction between different materials.

The material for manufacturing the separation layer is usually PVC plastic for armored cables. The thickness of this layer is usually from 1.0 – 1.8mm but plays a key role in maintaining the integrity of the electric cable.

Important applications:

- Prevent chemical reactions between armor metal and insulation material

- Protect internal cable components from force effects during cable manufacturing or installation construction.

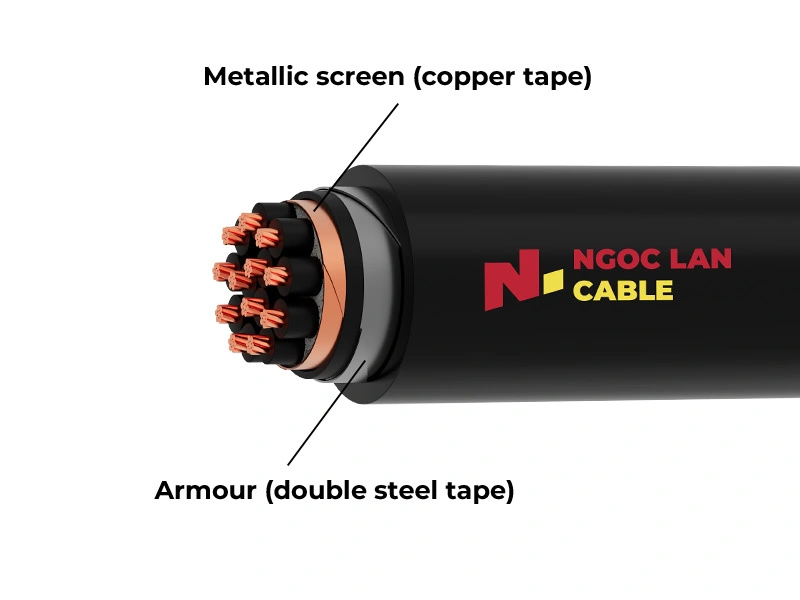

2.3. Metallic screen and armor protection

Metallic screen (electromagnetic interference screen) is a layer designed to prevent electromagnetic interference and protect the conductor from external impacts.

Materials used for metallic screens are usually copper or aluminum, with structures that can be in tape form, armor wires, or a combination of both tape and wires, or wires woven into mesh.

Armor protection is the strongest mechanical reinforcement layer in cable construction, designed to resist external mechanical impacts such as impact, pressure, animal gnawing, theft prevention… This component is especially important for underground cables and applications in harsh industrial environments.

The most common armor type is metal armor including double galvanized steel tape (DSTA), galvanized steel wire (SWA), double aluminum tape (DATA), aluminum wire (AWA)… twisted around the cable. Especially for single-core cables, the armor protection layer must be non-magnetic material.

3. Common electric cable classification based on construction

Distinguishing electric wire and electric cable based on construction is a key factor that helps you select optimal products for each project. Understanding the knowledge about internal structure not only directly relates to the practical application of electric cables but also helps you make accurate and economically efficient decisions.

3.1. Classification based on conductor structure

Conductor structure is the first factor that determines the mechanical and electrical properties of the cable.

Main structural types:

- Class 2 concentric stranded conductor cable

- Consists of wire numbers specified according to TCVN 6612 standard such as 7, 19, 37, 61… twisted together in a counter-clockwise direction

- High flexibility, suitable for various installation conditions

- Applications: Residential electrical systems, industrial

- Class 2 concentric stranded circular compacted conductor cable

- Wire numbers specified according to TCVN 6612 standard, then compacted to create a smooth round surface

- Increased conductive material density compared to regular stranded structure

- Better corrosion resistance due to fewer gaps

- Applications: Industrial electrical systems.

3.2. Classification based on number of cores

The number of conductor cores directly determines the cable's application capability in different electrical systems. Selecting the appropriate number of cores not only ensures transmission efficiency but also optimizes investment and operating costs for the project.

Detailed classification by number of cores:

- Single-core cable

- One single conductor with separate insulation

- Good heat dissipation, suitable for large currents

- Easy installation and maintenance

- Applications: High voltage transmission on power grids, system connections, control panels, machinery, equipment…

- 3-core cable

- Three conductors in one common sheath

- Suitable for balanced 3-phase systems

- Applications: Industrial motors, distribution systems

- 4-core cable (3 phase + 1 neutral)

- Three phase cores and one neutral/ground core

- Load balancing capability, voltage stability and safety assurance

- Applications: Residential electrical systems, commercial buildings

- Multi-core cable

- From 2 to 61 cores in one cable

- Each core has small cross-section (0.5 – 4.0 mm²)

- Optimal for signal transmission and control

- Applications: automation systems, machinery equipment

Core number selection guidelines:

- Determine electrical system type (single-phase, 3-phase, control)

- Calculate current and protection requirements

- Assess installation space and construction methods

- Consider material and labor costs

3.3. Classification based on sheath type

Sheath type is the factor that determines the cable's adaptability to specific working environments. Each sheath material has distinct characteristics regarding heat resistance, chemical resistance, fire resistance, and mechanical impact resistance.

Common sheath types:

- Standard PVC sheath cable

- Operating temperature: up to 70°C

- Low cost, easy processing and installation

- Good characteristics, stable electrical, mechanical and physical properties

- Applications: Fixed installation in buildings, workshops

- Heat-resistant XLPE sheath cable

- Operating temperature: up to 90°C

- High mechanical strength and lifespan

- Good UV resistance

- Applications: Outdoor lines, harsh environments

- HDPE sheath cable

- Operating temperature: up to 125°C

- Better mechanical strength than other PE types, good impact and abrasion resistance

- Good insulation and waterproofing. UV resistant

- Applications: Used in telecommunication cables, optical cables, medium voltage underground cables…

- Fire-resistant sheath cable

- IEC 60331 standard, no fire spread

- Maintains operation for 90-180 minutes during fire

- LSZH (Low Smoke Zero Halogen), FR-PVC (Fire resistant PVC) sheath…

- Applications: Fire alarm systems, emergency exits, hospitals, high-rise apartments…

Additionally, there are other types of electric cable sheaths such as rubber, nylon, PE (PolyEthylene), PUR (PolyUrethane), PP (PolyPropylene), PAR (PolyAmide Resin)…

| Environment | Temperature | Recommended sheath | Outstanding features |

|---|---|---|---|

| Indoor | 20-60°C | Standard PVC | Economical, easy construction |

| Outdoor | -20 đến 80°C | XLPE | UV resistant, good durability |

| Industrial | Variable | XLPE | Chemical resistant, good mechanical impact resistance |

| Safety | All conditions | LSZH, fire-resistant FR-PVC | Protects people and property during incidents |

4. Frequently asked questions about cable construction (FAQ)

4.1. How do insulation layer and sheath differ?

The insulation layer surrounds the conductor, functioning to electrically isolate between conductors or between the conductor and surrounding environment. The sheath is the outermost layer, undertaking the role of protection and resistance against mechanical impacts for the entire cable.

The main difference lies in purpose: insulation focuses on electrical properties (preventing leakage current), while the sheath primarily ensures mechanical properties (impact resistance, moisture resistance).

4.2. Copper core and aluminum core, which is better?

Copper core has 39% lower resistivity and high strength, suitable for industrial applications requiring high reliability. Aluminum core weighs 30% less and costs 30-40% less than copper, optimal for long-distance transmission lines and projects with cost-saving requirements.

Selection depends on specific requirements: copper for reliability, aluminum for economy. In practical applications, depending on project requirements, both materials are widely used and must comply with TCVN/IEC technical standards to ensure safe use.

4.3. Do all electric cables have exactly 3 parts?

No. The basic 3-part construction applies to conventional cables (conductor, insulation, sheath). Specialized cables have additional components such as metallic armor, filler, separation sheath, screen… depending on environment and specific technical requirements.

Examples: Underground cables have additional steel armor, control cables have additional filler, interference-resistant cables have additional conductor screen.

4.4. Do residential and industrial electric cables have different constructions?

Residential cables have simple 2-part construction, 220V/380V voltage, standard PVC sheath, focusing on economy and easy installation. Industrial cables are more complex with 4-7 layers, 1kV-35kV voltage, with additional armor protection or filler, separation layer…

This difference comes from different requirements for working environment, safety level, and service life between the two applications.

5. Conclusion: Master the construction for effective application

How many parts does an electric cable structure consist of depends on the cable type and specific application. The three core components – conductor, insulation layer, and sheath – form the foundation for all types of standard electric cables, ensuring transmission efficiency and operational safety.

Auxiliary components such as filler, armor protection, and separation layer are added when needed to meet special requirements for durability, interference resistance, or safety in harsh environments. Understanding each component clearly helps you identify product quality, select appropriate electric cables, and ensure safe operation according to TCVN standards.

With a commitment to quality and technical expertise, Ngoc Lan Cable is always ready to support you in learning details about high-quality electric cable products, or contact our engineering team directly for optimal solution consultation for specific projects.

VN

VN