Ampacity is a critical parameter that must be thoroughly understood when designing, installing and operating electrical systems using aluminum aerial bundled cables. So what is the ampacity of ABC cables and how can it be accurately looked up? This article provides comprehensive information about ampacity, the factors influencing it, and step-by-step instructions on how to properly use the ampacity chart for aluminum aerial bundled cables. Understanding and correctly applying this parameter is essential to ensure the safe operation and longevity of your electrical projects and systems.

1. What is the ampacity of aluminum aerial bundled cables?

The ampacity of an aluminum aerial bundled cable (ABC cable) is the maximum current the cable can carry without exceeding the allowable temperature limit of the insulation. This is a fundamental and critical technical parameter that ensures safety and performance when selecting cables for an electrical system.

When an electric current flows through a conductor, heat is generated due to the Joule effect (P = I²R). If the current exceeds the rated value, the cable temperature will rise significantly, potentially causing damage to the insulation, reducing the cable's lifespan, and even leading to fire or explosion hazards.

For example, a 4-core aluminum aerial bundled cable with a 50mm² cross-section has an ampacity of approximately 150A under an ambient temperature of 30°C. This means that a current larger than 150A should not be allowed to flow through this cable for an extended period to ensure safety.

2. Factors affecting the ampacity of aluminum aerial bundled cables

The ampacity of aluminum aerial bundled cables is not a fixed value but depends on various factors. Understanding these factors allows you to more precisely calculate the current carrying capacity of the cables under specific conditions.

2.1 Conductor cross-section

The cross-sectional area of the conductor is the factor that most directly affects ampacity. As the cross-section increases, the current carrying capacity also increases because the electrical resistance decreases and the heat dissipation improves.

The formula for calculating the resistance of a conductor:

R = ρ × L/S

Where:

- R: resistance (Ω)

- ρ: resistivity of the conductor material (Ω.mm²/m)

- L: length of the conductor (m)

- S: cross-sectional area of the conductor (mm²)

2.2 Ambient temperature

The surrounding ambient temperature has a major influence on the current carrying capacity of the cable. Typically, the ampacity is specified at a standard ambient temperature (usually 30°C). As the ambient temperature increases, the cable's ability to dissipate heat decreases, leading to a reduction in ampacity.

2.3 Installation method

The cable installation method affects the cable's heat dissipation ability. Common installation methods include:

- Aerial installation (suspended on utility poles)

- Direct burial in the ground

- Installed in conduits

- Installed on cable trays

Each method has a different adjustment factor for the ampacity.

3. Instructions for looking up the ampacity of aluminum aerial bundled cables

Checking the ampacity of aluminum aerial bundled cables is an important step to ensure the electrical system operates safely and efficiently. Below is the detailed checking procedure:

Step 1: Identify the cable's technical specifications

The first step is to correctly determine the technical specifications of the aluminum aerial bundled cable being used. This information is usually printed on the cable sheath or can be found in the manufacturer's technical documentation. The information to gather includes:

- Conductor cross-sectional area (mm²)

- Number of cores

Step 2: Check the installation conditions

Take note of the actual installation conditions of the cable, such as whether it is aerial installation, in cable trays, in conduits, or direct buried, etc.

Step 3: Look up the basic ampacity value

Based on the identified technical specifications and installation conditions, look up the basic ampacity value from the standard reference table or the manufacturer's documentation. Note that this value is usually given under standard conditions (ambient temperature of 30°C and a specific installation method).

4. Aluminum aerial bundled cable ampacity chart

The ampacity chart is an essential tool to help technicians and electrical engineers quickly and accurately determine the current carrying capacity of aluminum aerial bundled cables. Below is a detailed table of specifications for 2-core, 3-core, and 4-core XLPE insulated aluminum aerial bundled cables.

5. Frequently asked questions (FAQs)

5.1 How to check the ampacity of installed aluminum aerial bundled cables?

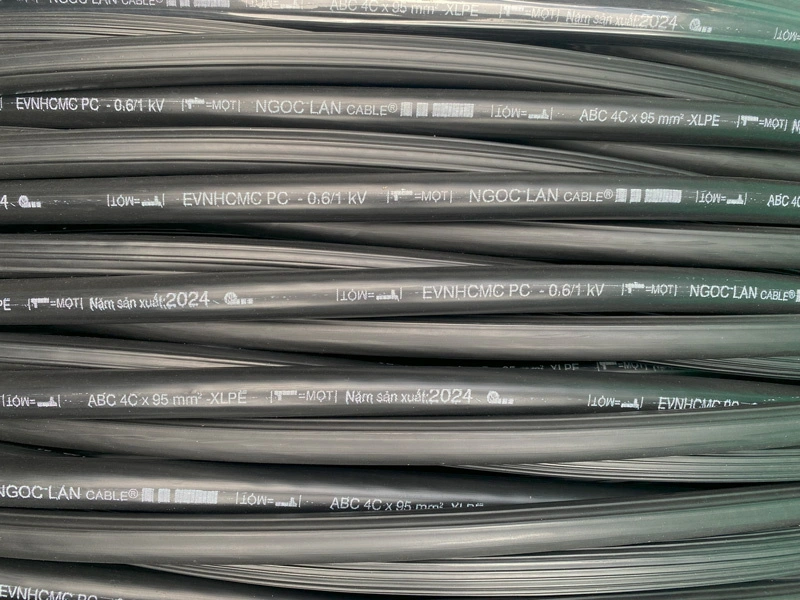

Step 1: Identify the information printed on the cable sheath:

- Carefully check the cable sheath for printed information about the cross-section, rated voltage, and ampacity.

- If the information is faded or unreadable, use the cable's color, diameter, and code (if available) to accurately identify the type and look up the manufacturer's documentation.

Step 2: Check the actual installation conditions and configuration:

- Consider whether the cable is aerial installed or direct buried. The ampacity will differ depending on the installation configuration.

- Check the surrounding ambient temperature, as the ampacity is determined at a standard temperature (usually 30ºC). If the actual temperature is higher, the ampacity needs to be adjusted downward.

- For cables installed in the same trench/duct bank, consider the thermal influence of adjacent cables and adjust the ampacity according to the corresponding factor table.

Step 3: Look up the ampacity chart:

Based on the identified cross-section, cable type, and actual installation conditions, find the corresponding ampacity chart.

5.2 Is it okay to use aluminum aerial bundled cables beyond their ampacity?

Using aluminum aerial bundled cables frequently beyond their ampacity can lead to some serious consequences such as:

- Overheating: Operating aluminum cables above their ampacity causes a sudden temperature increase, leading to the risk of cable sheath burning and fire hazards.

- Reduced cable lifetime: Cables age rapidly due to overheating and electrical discharge when frequently carrying overload currents. The insulation and sheath quickly deteriorate, prone to short circuits and leakage, resulting in costly warranty replacements, safety issues, and electrical hazards.

- Losses and reduced efficiency: Power losses due to the Joule effect increase significantly when the load current is high, reducing transmission efficiency and increasing electricity costs. High currents also cause electromagnetic interference, phase imbalance, and voltage drops on the grid, degrading power quality.

6. Conclusion

The aluminum aerial bundled cable ampacity chart is a useful and indispensable tool for engineers, electrical system contractors, and especially those new to the electrical industry who need to thoroughly understand it. Mastering how to flexibly look up and apply the chart, combined with knowledge of the influencing factors, will help you accurately determine the ampacity parameter, thereby selecting the appropriate cable cross-section for each specific condition and application. This is crucial to ensure the electrical system operates safely and extends its service life.

VN

VN