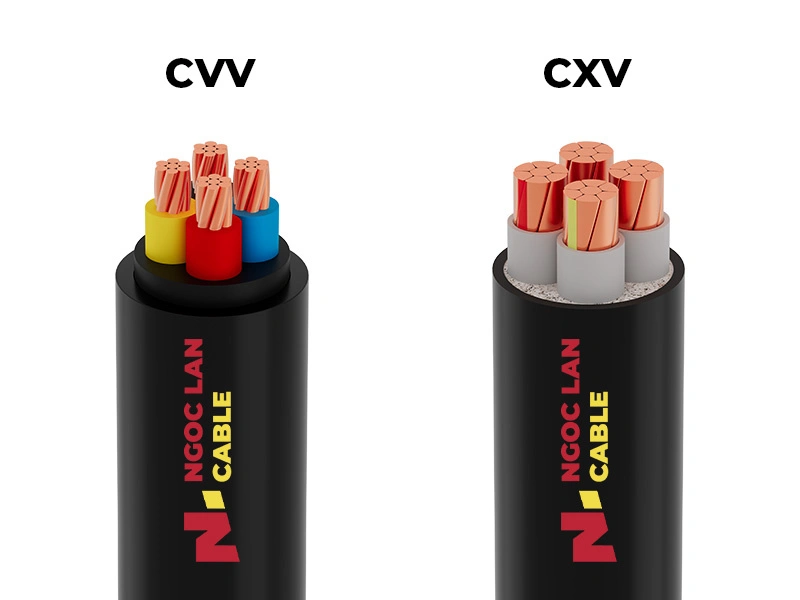

Understanding clearly how CVV and CXV cables differ is a crucial factor for selecting appropriate electrical cables for all construction projects, avoiding common mistakes that can affect safety and costs.

With over 30 years of experience in manufacturing low voltage cables and medium voltage cables, Ngoc Lan Cable's technical team has compiled these guidelines to help you clearly distinguish between these two electrical cable types through important aspects:

- Clear explanation of structural differences: XLPE insulation layer of CXV cable and PVC of CVV cable

- Technical performance analysis: Heat resistance capability, durability and actual current carrying capacity

- Practical applications: When to use CVV to optimize costs and when CXV is needed for high performance

In practice, choosing the wrong cable type can lead to serious consequences from system overload to fire and explosion risks. This article will help us understand the core differences between these 2 cable types.

1. Structure of CVV and CXV cables

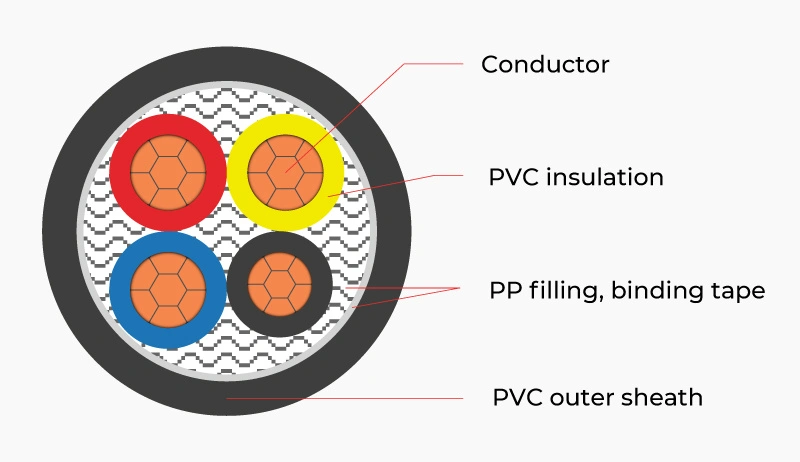

1.1. CVV cable

CVV electrical cable (Cu/PVC/PVC) is constructed with a copper conductor, covered with two layers of PVC plastic – one insulation layer and one protective sheath layer. This simple structure provides high flexibility during installation and reasonable cost, making CVV a popular choice for many low-voltage electrical applications in residential and commercial projects.

For detailed structure reference: What is CVV Electrical Cable?

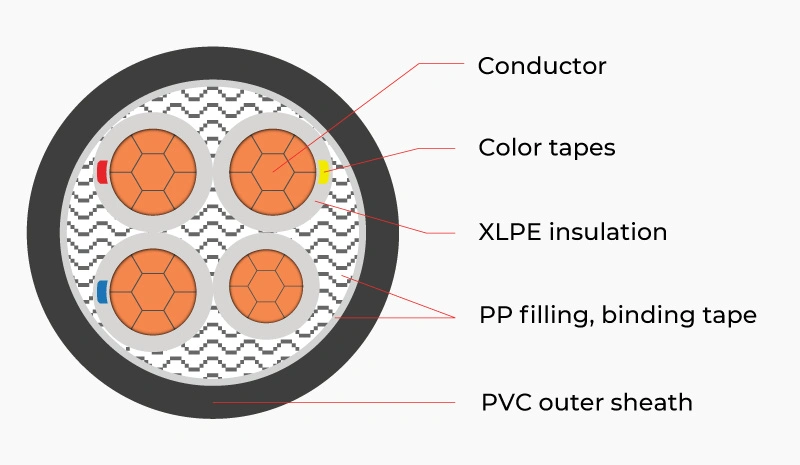

1.2. CXV cable

Similar to CVV, CXV cable (Cu/XLPE/PVC) also uses copper conductor and PVC outer sheath, but the key difference lies in the insulation layer made from XLPE (Cross-Linked Polyethylene). This material has a more durable molecular structure, providing superior heat resistance up to 90°C and significantly higher mechanical strength compared to PVC, making it particularly suitable for industrial applications requiring high performance.

Detailed analysis of CXV advantages: What is CXV cable wire?

2. Technical specification comparison table between CVV and CXV

The different insulation materials create distinct performance differences. The table below compares important technical characteristics to help you make accurate decisions.

Detailed technical specification comparison table

| Technical Characteristics | CVV Cable | CXV Cable |

|---|---|---|

| Long-term operating temperature | 70°C | 90°C |

| Maximum short-circuit temperature in 5s for conductor | 160°C | 250°C |

| Current carrying capacity | Standard | 15-30% higher |

| Mechanical strength | Good | Very good |

| Water resistance | Average | Good |

| Dielectric loss | Higher | Lower |

| Bending radius | Small (flexible) | Larger (stiffer) |

| Expected lifespan | ~20 years | >30 years |

Brief Analysis:

CXV cable excels in heat resistance and current carrying capacity. CVV cable has advantages in economics and installation flexibility.

3. When to choose CVV, when to use CXV?

Selecting the correct cable type ensures technical safety while optimizing project investment costs.

Cable selection table by application

| Application | Recommended choice | Reason |

|---|---|---|

| Residential electrical systems | CVV cable | Stable environment, light load, cost priority |

| Industrial plant electrical systems | CXV cable | High temperature, heavy load, continuous operation |

| High-power motor power supply | CXV cable | Withstands high starting current, high heat generation |

| Direct underground installation | Armoured CXV | High mechanical strength, good water resistance |

| Public lighting | CVV cable | Light load, cost savings with appropriate protection |

Therefore, to summarize: CVV is suitable for light load applications and stable environments. CXV cable is the mandatory choice for systems requiring high performance.

4. Cost factors

Cost is always an important factor influencing purchasing decisions, so understanding clearly why there is a price difference between the two cable types will help you make the appropriate choice.

CXV cable prices are 20-30% higher than CVV. This is due to superior XLPE material and more complex manufacturing processes. This price difference is proportional to the benefits in performance and longer lifespan, helping reduce long-term maintenance costs.

Ngoc Lan Cable currently manufactures both product lines with quality meeting TCVN 5935-1, TCVN 6612, TCVN 5933 standards. Our cables can extensively meet demands from low voltage power cables for civil construction to medium voltage power cables serving industrial zones.

5. Frequently asked questions

5.1. Can CXV cable be installed directly underground?

Yes, CXV cable can be installed directly underground thanks to XLPE's good moisture resistance. However, it is recommended to use armoured types (DSTA – Double Steel Tape Armour, DATA – Double Aluminum Tape Armour, SWA – Steel Wire Armour…) to enhance mechanical protection.

5.2. Can CVV be used to replace CXV?

Absolutely not. It cannot be substituted in places requiring temperatures above 70°C, as arbitrary replacement poses serious risks of overload and fire hazards.

6. Conclusion

CVV and CXV cables differ in their insulation layers, which determines the performance of the entire system. In practical project implementation, we frequently encounter system failures due to inappropriate selection between these two cable types.

Choosing the correct cable type not only ensures operational safety but also optimizes investment costs. A wise decision will bring long-term efficiency to the entire electrical system.

Effective selection process:

- Determine technical requirements: Analyze installation environment, operating temperature, and system current load requirements

- Cross-reference applications: Use the cable selection table by application to choose the appropriate cable type for the project

- Calculate long-term investment costs: Consider initial investment costs against benefits in lifespan and operational performance

Need in-depth consultation for your specific project? Contact Ngoc Lan Cable's technical team immediately to receive the most optimal solution for each individual application.

VN

VN