Have you ever thought that a small mistake in the process of installing electrical cables could also cause unimaginable consequences? From electric shock accidents to the risk of fire and explosion, the lack of safety knowledge when working with electrical systems can turn a simple job into a disaster. Let's explore the safety precautions when installing cables with Ngoc Lan Cable to protect yourself and those around you.

1. Disconnect power before installation

This is the first and most critical step when installing electrical cables. Disconnecting power helps prevent electric shock and other serious related accidents.

To ensure absolute safety, you need to follow this power disconnection procedure:

- Turn off the main switch, circuit breaker, and related power cutoff devices at the installation site.

- Lock and tag (lockout/tagout) the power cutoff devices to prevent others from accidentally turning power back on.

- Use a voltage tester to confirm there is no electricity at the connection points before beginning cable installation.

By properly following the power disconnection procedure, you have eliminated the biggest hazard when working with electrical systems.

2. Use personal protective equipment (PPE)

When working with electrical systems, having and properly using personal protective equipment (PPE) is extremely important to avoid dangers to yourself.

The basic PPE items you must have include:

- Insulated gloves to prevent electric current from passing through the body.

- Electrical safety shoes to protect the feet when working in environments with high risk of electric leakage or transmission.

- Insulated protective clothing to protect the worker's body while working.

- Safety glasses to prevent fogging, UV rays, scratches, etc. Note that to ensure vision, electricians should use clear lenses in low light areas and tinted lenses when working outdoors.

- Hard hats to protect the head from impact injuries and falling heavy objects from above.

- Safety harness to balance the whole body for workers at heights and allow working at heights for extended periods.

When selecting PPE, you need to choose the appropriate sizes and ensure they are intact, show no signs of damage, and inspect the PPE before each use. You should also consult with reputable suppliers to select PPE that meets safety standards for your work.

3. Inspect tools and equipment before use

Before starting the installation process, you need to thoroughly check electrical tools and equipment to see if they are working properly. Some points to check include:

- Voltage tester: test on a known power source to ensure it indicates the correct voltage.

- Clamp meter, VOM: check function and calibration before use.

- Visually inspect hand tools like screwdrivers and pliers for wear or damage. Discard any defective tools.

To facilitate inspection, you can create a checklist to verify tools before each work shift. This helps ensure tools are always in a ready state and avoids errors due to forgetting to inspect.

4. Follow lockout/tagout (LOTO) procedures

Lockout/tagout (LOTO) is a procedure to control hazardous energy, ensuring electrical equipment has been disconnected from power and is safe to perform maintenance or installation work on.

The basic LOTO procedure according to OSHA (Occupational Safety and Health Administration) standards consists of the following steps:

Step 1: Prepare

- Identify the equipment, system requiring maintenance and related energy sources.

- Notify employees so everyone is aware of the information.

- Consider the specific hazards and the means and machinery to control those hazards.

Step 2: Shut off power

- Turn off the equipment according to standard operating procedures.

- Disconnect all energy sources to the equipment (electrical, compressed air, hydraulic, thermal, chemical, mechanical, etc.)

- Notify affected employees about the shutdown so they can prepare for their work.

Step 3: Isolate the equipment's energy sources

- Isolate the machine or equipment from any energy sources such as turning off power at the circuit breaker or closing valves.

- For energized equipment: Never stand directly in front of the switch to prevent the risk of arc flash. In cases of locking out high voltage electricity, personal protective equipment (PPE) must be used.

Step 4: Lock and tag

- Lock energy isolation devices with a personal lock.

- Use a lockout lock and attach a tagout tag with information about the person performing it and the reason for locking the equipment.

Step 5: Verify and confirm the equipment is de-energized.

- Double check to ensure all related energy sources have been disconnected and locked out.

- Attempt to operate to make sure the equipment is safe.

Step 6: Perform the work: install or maintain cables.

After verifying the equipment is de-energized and safe, proceed with installing and maintaining the cables.

Step 7: Notify and remove locks

- Carefully inspect to make sure no one is in the danger zone and equipment and tools must be removed before restarting

- Remove the locks

- Notify affected employees about the maintenance before restarting.

Each employee needs to be trained to clearly understand their role in the LOTO procedure. Note carefully, only the person who attached the lock and tag has the right to remove that exact lock.

5. Prevent arc flash hazards

Arc flash is one of the most serious hazards when working with electrical equipment. It is a plasma fireball with temperatures up to 19,500°C, which can cause severe burns and serious injury if exposed.

To reduce the risk of arc flash, you need to:

- Wear appropriate arc flash PPE such as clothing, gloves, and thermally insulated and insulated hats.

- Use measuring devices and arc flash analysis tools to assess arc flash risks according to NFPA 70E standards.

- Properly follow LOTO procedures when working.

- Avoid working in areas with limited space and restricted egress.

- Avoid allowing conductive tools to come into contact with energized conductors, causing a short circuit.

6. Post-installation assessment and maintenance

To ensure the safety and performance of the cable system, you need to conduct periodic inspections and maintenance after installation:

- Evaluate installation quality: Check the tension, sag, and connections of the conductors, mechanical and electrical standards.

- Measure electrical parameters: rated current, voltage, insulation resistance, earth resistance.

- Regular insulation cleaning: remove dirt and water from the surface of conductors and termination equipment.

- Maintain switching equipment and connectors: clean contacts, replace lubricants, test operation.

- Assess upgrade needs: periodically review the condition of the system and make appropriate upgrade plans.

A safe and reliable system is the result of a thorough, professional installation, inspection and maintenance process.

7. Frequently asked questions (FAQs)

7.1 Should I install electrical cables myself at home or hire a professional service?

If you do not have the expertise and experience working with electrical systems, it is best to use the services of a professional electrician for installation. Improper installation can be dangerous for you and your family. Some risks that may occur include:

- Risk of electric shock, fire and explosion due to incorrect connections or short circuits.

- Overloading causing damage to electrical equipment and conductors.

- Violating technical and electrical safety standards.

- Inability to handle unexpected incidents.

Hiring a reputable electrician will help you install cables with proper technique, ensure safety, and provide full warranty paperwork. The cost will be slightly higher than doing it yourself, but in the long run it is completely worth it to ensure the quality and longevity of your home's electrical system.

7.2 What are the abnormal signs of electrical cables to watch out for?

When using an electrical system, you need to pay attention to some signs warning of damage or overload of the line such as:

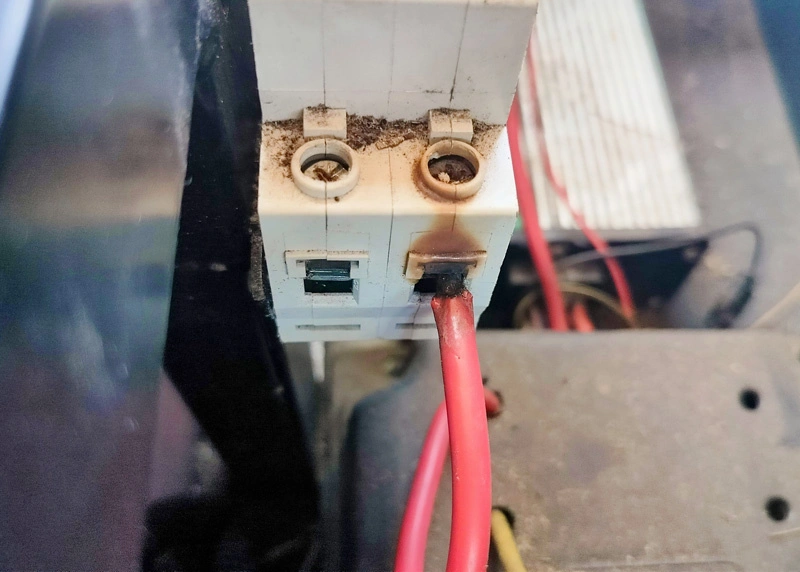

- Heating up, discoloration or blistering of the electrical cable sheath.

- Burning smell emitted from outlets or electrical equipment during operation

- Switches or circuit breakers getting stuck or difficult to turn on and off

- Electrical panels and junction boxes with water or insect intrusion

- Operating current exceeding the rated capacity of conductors and switching devices

- Abnormal shaking or sagging of overhead wires

If you notice any of the above abnormal signs, immediately report it to experienced electrical professionals such as electricians or the nearest electrical authorities to conduct an inspection and repair.

7.3 How to choose appropriate Electrical PPE?

Identify hazards and assess risks:

- Analyze the job to identify potential hazards such as electric shock, arc flash, electromagnetic fields, thermal burns, etc.

- Assess the level of risk for each hazard to select the type and level of protection for PPE.

Choose PPE that meets technical standards:

- PPE must be certified to meet Vietnamese standards (such as TCVN, QCVN) and international standards (such as IEC, ANSI, NFPA, ASTM).

- These standards ensure PPE is designed, manufactured and tested to achieve the required protective performance.

Select the appropriate type of PPE for the working voltage level:

- For low voltage under 1000V: Insulated gloves, insulated boots, insulated hat, arc flash goggles/face shield.

- For high voltage over 1000V: Add arc flash resistant full body suit, arc flash blankets and barriers.

Equipping and using appropriate electrical PPE is an important part of an electrical safety management system, helping prevent and minimize serious injuries to workers when working in contact with or near energized areas.

8. Conclusion

Through this article, we have gained a clear understanding of the safety precautions when installing electrical cables. From disconnecting power, using personal protective equipment, inspecting tools, to following lockout/tagout procedures and preventing arc flash.

Whether you are a professional electrician or simply interested in electrical safety, hopefully this article has provided you with useful and practical knowledge. Remember that safety in electrical cable installation is not only a professional responsibility but also a way to protect the lives of yourself and those around you. Always follow the rules, be fully equipped, and be conscious is the key to preventing unfortunate accidents from happening.

VN

VN