Have you ever wondered why certain electrical cables can withstand significant pressure when buried underground or operate reliably in harsh environments? The answer lies in the cable's protective armor layer – DSTA.

In this article, we will explore the concept of DSTA, its unique structure, outstanding advantages, comparison with DATA, and practical applications in infrastructure projects. First, let's delve into the unique physical structure of this technology.

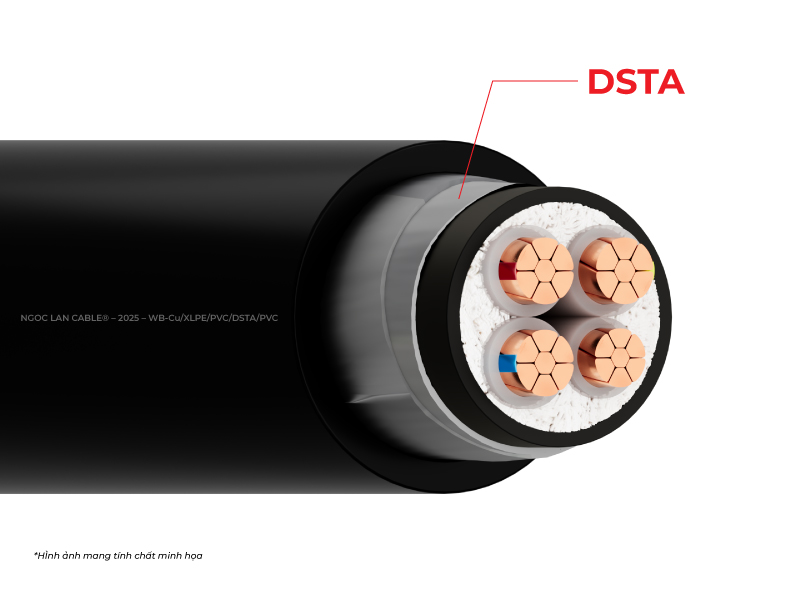

1. Physical structure of DSTA

DSTA is a cable protection armor designed according to the “double helix” principle with two symmetrically spiraled steel layers. To understand how it works, observe the cross-section of the WB-CXV/DSTA — 0.6/1kV underground cable structure.

To accurately assess the protective capabilities of the DSTA system, we need to examine the detailed technical specifications of each steel tape layer:

| Parameter | Inner Layer | Outer Layer | Test Standard |

|---|---|---|---|

| Thickness | 0.3mm | 0.5mm | IEC 60502 |

| Twist angle | 30° | 25° | TCVN 5935-1 |

| Breaking load | 450N/mm² | 500N/mm² | TCVN 5935-2 |

| Elongation | 15% | 12% | IEC 60502 |

| Wear resistance | 20D | 25D | TCVN 5935-1 |

Based on the cross-sectional image and technical specifications table, we can see that the “double helix” in the DSTA structure creates a concentric defense system. The inner steel tape layer (0.3mm) with a 30° winding angle forms the basic protection layer, while the outer layer (0.5mm) with a 25° winding angle adds another defense layer. This design ensures there are no weak points in the structure and enhances the ability to resist mechanical impacts.

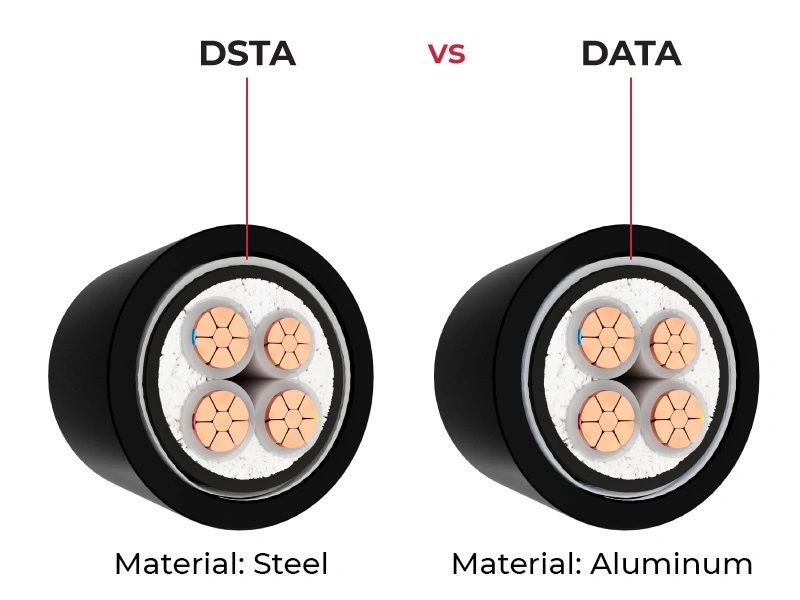

2. Comparison of DSTA and DATA

In the electrical cable industry, choosing between DSTA and DATA (Double Aluminium Tape Armoured) depends on many factors. Let's analyze in detail the differences between these two technologies through the detailed technical comparison table below to make the most appropriate decision.

| Criteria | DSTA | DATA | Notes |

|---|---|---|---|

| Total thickness | 0.8mm | 0.5mm | DSTA is thicker, providing better protection |

| Impact resistance | >100J/m² | >70J/m² | DSTA excels in harsh environments |

| Mechanical | >500N/mm² | >350N/mm² | DSTA is suitable for strength high loads |

| Corrosion resistance | Xuất sắc (>1000h SST) | Tốt (>750h SST) | SST: Salt Spray Test |

| Manufacturing cost | 130-150% | 100% | DATA là cơ sở tham chiếu |

From the comparison table, we can see that DSTA demonstrates superior performance in harsh environments thanks to significantly higher impact resistance and mechanical strength. The two-layer steel structure not only provides better protection but also ensures longer service life in harsh working conditions. Although the cost is 30-50% higher than DATA, DSTA is the optimal choice for projects requiring high reliability and long service life, such as urban underground cable systems or industrial plants.

After understanding the differences between these two types of electrical cable armor, let's explore the distinctive advantages and factors to consider when using DSTA in practical applications. This will help you make more informed decisions when choosing the appropriate electrical cable protection solution.

3. Advantages and disadvantages of DSTA armor

After analyzing the structure and comparing it with alternative solutions, we need to comprehensively evaluate the outstanding advantages as well as points to consider when using DSTA in practical applications.

Outstanding advantages

DSTA is designed to meet stringent requirements in harsh installation environments. Below are the main advantages of this technology:

| Criteria | Details |

|---|---|

| Mechanical protection capability | – Resists direct impact with force >100J/m² – High compression resistance due to double helix structure – Distributes force evenly across the entire cable surface |

| Corrosion resistance features | – Passes salt spray test >1000 hours (Salt Spray Test) – Resists electrochemical corrosion in soil Effective protection in acidic/alkaline environments |

| Environmental durability | – Operates stably at temperatures from -40°C to +90°C – Absolute water resistance when buried – Technical lifespan over 25 years under normal working conditions |

Factors to consider

Although DSTA provides many benefits, there are some limitations that need to be considered during the design and construction process:

| Criteria | Details |

|---|---|

| Installation technique | – 40-50% heavier than standard cable – Requires larger minimum bending radius (>15D) – Specialized equipment needed for construction |

| Investment costs | – Material costs 30-50% higher than conventional solutions – Requires highly skilled technicians for installation – Higher periodic maintenance costs |

4. Practical applications of DSTA armored cable

Below are three typical examples of DSTA armored cable applications in infrastructure projects in Vietnam. The information is taken from the national bidding network system of the ministry of planning and investment.

Example 1: Project in Hung Yen Province

| Project Information | |

|---|---|

| Project name | Regular management and maintenance of road transport infrastructure |

| Number TBMT | IB2400567941 |

| Code KHLCNT | PL2400306934 |

| Investor | Department of transport of Hung Yen Province |

| Bid solicitor | Project management board for transport engineering works |

| Project location | Hung Yen Province |

| Technical Specifications | |

| Material name | Underground cable Cu/XLPE/PVC/DSTA/PVC 3×35+1×25-0,6/1kV |

| Cable installation | 100m |

| Installation depth and width | ≤1m |

Example 2: Project in Bao Lam District, Lam Dong Province

| Project Information | |

|---|---|

| Project name | Package No. 01 — All costs for construction, supply, installation of high-altitude surveillance camera system |

| Number TBMT | IB2400584715 |

| Code KHLCNT | PL2400317224 |

| Investor | People's Council Office and People's Committee of Bao Lam District |

| Bid solicitor | HUNG DUNG LAM DONG CO., LTD |

| Project location | Bao Lam District, Lam Dong Province |

| Technical Specifications | |

| Material name | Electrical cable AC 2x6mm² (CXV/DSTA) |

| Cable installation length | 442m |

Example 3: Project in Cam Lam District, Khanh Hoa Province

| Project Information | |

|---|---|

| Project name | Project name Public service 2024. Items: Maintenance, operation and repair, replacement of traffic signal lights, lighting system and decorative LED boards in 2024 |

| Number TBMT | IB2500009382 |

| Code KHLCNT | PL2500003294 |

| Investor | Investor Department of Economics and Infrastructure of Cam Lam |

| Bid solicitor | Department of Economics and Infrastructure of Cam Lam |

| Project location | Cam Lam District, Khanh Hoa Province |

| Technical Specifications | |

| Material name | Underground 4-core cable, CVV/DSTA 4x25mm² |

| Cable installation length | 45m |

| Installation depth and width | ≤1m |

Results from the above projects show that DSTA operates stably under real conditions, meeting requirements for mechanical strength and corrosion resistance well. All projects reported high efficiency in protecting electrical cables from environmental and mechanical impacts.

With the promising results from real projects, we will continue to explore the quality standards that DSTA needs to meet.

5. DSTA quality standards

You have seen that DSTA provides many important benefits in protecting electrical cables from mechanical impacts and harsh environments. However, to ensure the performance and safety of the cable, compliance with national and international standards is mandatory.

Standard levels

| Standard Level | Details |

|---|---|

| Mandatory | – TCVN 5935-1:2013 (underground low voltage) – TCVN 5935-2:2013 (underground medium low voltage) |

| Recommended | – IEC 60502 (power cables with voltages from 1kV to 30kV) |

| Additional Testing | – Bending, tensile, and impact testing – Mechanical strength testing |

Acceptance process for DSTA cables

The acceptance process for cables using DSTA armor includes the following main steps:

1. Document and standard verification:

-

- Determine technical standards according to TCVN 5935-1 or TCVN 5935-2.

- Check quality certificates (CO/CQ) and insulation resistance test reports.

- External inspection:

- DSTA armor must consist of two spiral steel tape layers, 0.2–0.8 mm thick, with 100% coverage.

- PVC/HDPE jacket must be free of cracks, deformation, or abrasion.

2. External inspection:

-

- DSTA armor consists of two spiral steel tape layers, 0.2–0.8 mm thick, with 100% coverage.

- PVC/HDPE jacket free of cracks, deformation, or abrasion.

3. Electrical testing:

-

- Measure insulation resistance ≥1 MΩ (low voltage cable).

- Test dielectric strength: DC voltage test (e.g., 3.5 kV for 5 minutes for 0.6/1 kV cable).

4. DSTA armor core inspection:

-

- Thickness and material: Non-rusting steel tape, thickness 0.2–0.8 mm according to TCVN 5935-1.

- Winding method: Two overlapping spiral tape layers, spacing between turns ≤50% of tape width.

5. Load capacity verification:

-

- Continuity: Determine the continuity of the conductor and ground wire.

- Bending radius: Ensure ≥12 times cable diameter to avoid damage to the armor layer.

Understanding these quality standards will help you choose the right type of cable using DSTA or other armor suitable for your project. So what other common questions relate to DSTA?

Currently, Ngoc Lan Cable offers electrical cable products using DSTA armor that you can reference:

6. Frequently asked questions about DSTA

Below are some common questions related to DSTA along with brief answers to help you better understand this protective armor

1.Can DSTA be used in acidic environments?

Electrical cables with DSTA armor can be used in acidic environments if the armor is made of high-quality stainless steel (e.g., SUS 316) and the outer jacket is synthetic rubber/LSZH to isolate the acid. However, for concentrated acids (H₂SO₄ >50% or HCl >20%), additional protection measures such as conduit or switching to non-metallic armor materials are required.

2. Why is DSTA better than SWA at depths >2m?

DSTA is superior to SWA at depths >2m due to its structure of two spiral steel tape layers with 100% coverage, helping to distribute pressure evenly and resist deformation under high ground pressure. In contrast, SWA is easily deformed by pressure from soil and rocks, and gaps between steel wires create pathways for water infiltration.

3. How to check the quality of cables using DSTA?

Quality checking for electrical cables with DSTA includes:

-

- Visual inspection: Confirm 2 spiral steel tape layers, 0.2–0.8 mm thickness, and PVC/HDPE jacket without cracks.

- Electrical testing: Measure insulation resistance ≥1 MΩ (low voltage cable) and dielectric strength testing (e.g., 3.5 kV DC for 5 minutes).

- Mechanical testing: Ensure compression resistance ≥500 N/m and water resistance after 24h immersion.

4. Is regular maintenance required for cables with DSTA?

Periodic DSTA maintenance is necessary to ensure safe and sustainable operation of the electrical system, especially in harsh environments. Maintenance frequency should be adjusted based on installation conditions:

-

- Normal environment (dry, non-corrosive): Maintenance inspection every 12–24 months after installation.

- Harsh environment (humid, acidic, heat >60°C): Maintenance inspection every 6–12 months after installation.

These questions reflect practical user concerns, helping you better understand the role and applications of DSTA.

Understanding common questions will help you be more confident when selecting and using electrical cables with DSTA in specific projects.

7. Conclusion

You have seen that DSTA provides many important benefits in protecting electrical cables from mechanical impacts and harsh environments. This is a double armor layer of two spiral steel tapes, designed to enhance strength and longevity for cables.

Through the information shared above, we hope you now have a better understanding of DSTA:

- Physical structure: Two spiral steel layers with a “double helix” effect that helps distribute force more evenly.

- Outstanding advantages: Corrosion resistance, high pressure tolerance, and compatibility with various installation environments.

- Quality standards: Electrical cables using DSTA meet international standards such as IEC 60502-1, IEC 60228/TCVN 6612, and Vietnamese standards such as TCVN 5935-1:2013, TCVN 5935-2:2013.

Ngoc Lan Cable is proud to provide electrical cable products with DSTA armor that meet safety standards and optimal performance for all projects.

If you want to learn more about how to apply electrical cables with DSTA or need detailed consultation, don't hesitate to contact industry experts for support!

VN

VN