- Detailed structure – 3 structural layers from copper conductor to PVC sheath

- CVV and CXV classification – Differences between PVC insulation (70°C) and XLPE (90°C)

- Cross-section selection – Guidelines based on load capacity and applications

You will also learn about frequently asked questions regarding installation methods and distinguishing genuine cables. To select the right cable type for your project, the first step is understanding its technical structure thoroughly.

1. What is 4-core wire? Detailed structure analysis

4-cores wire is a type of cable with 4 separate electrical conductors, each insulated and enclosed together within a protective sheath. This is a specialized cable structure designed to transmit electrical power for three-phase systems with neutral wire.

Three-phase electrical systems need to transmit 3 phase currents and 1 neutral current simultaneously. Therefore, the 4-core structure meets both high-power energy demands and complex control requirements.

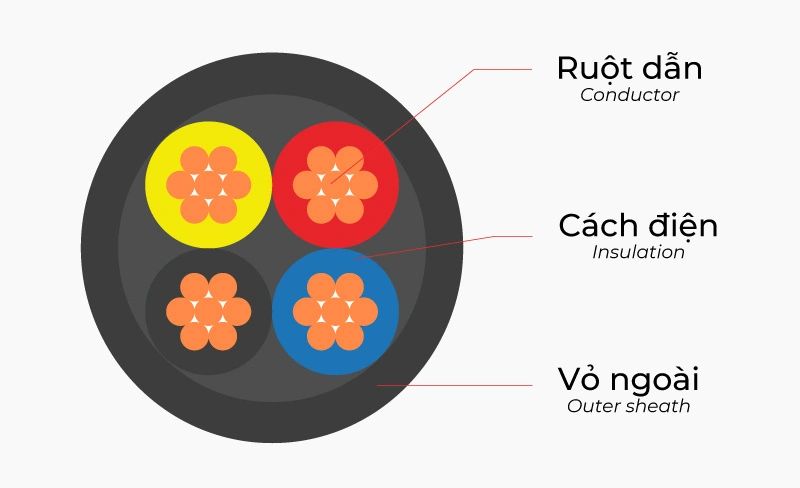

The structure of 4-cores wire consists of 3 layers, each layer performing a specific role in safe electrical transmission.

Key point: 4-cores wire is designed to serve 3-phase systems with L1-L2-L3-N configuration. Where the 3 phase wires carry alternating current with 120° phase shift, while the neutral wire provides a return path for electrical current. Thanks to this structure, 4-cores cable not only ensures safety for electrical equipment but also optimizes power transmission capability in industrial projects.

1.1. Conductor

4-cores copper cable uses copper as the main material for conductors. Copper conductors must comply with TCVN 6612 standard to ensure technical requirements and safety in use.

Additionally, some large electrical cables serving construction projects, power grids, underground installations… may also use aluminum as conductors to optimize costs.

1.2. Insulation

The insulation layer individually wraps each conductor to prevent electrical leakage. Common materials for this layer are PVC or XLPE. XLPE insulation withstands heat 20°C better than PVC. Therefore, XLPE is suitable for high-temperature environments.

1.3. Outer sheath

PVC sheath is commonly used as the protective layer shielding the cable from mechanical impacts and environmental conditions such as moisture resistance, chemicals, and impacts during operation.

2. Classification of 4-cores wire: When to use CVV and CXV cables?

4-cores electrical wire are classified based on insulation material – a factor directly affecting heat resistance, dielectric strength, and application environment. Understanding each cable type helps engineers select the right type for residential, industrial, or underground installation systems, ensuring long-term performance and electrical safety.

2.1. Types of 4-cores wire

Currently, the two most common 4-cores cable lines are CVV (PVC insulation) and CXV (XLPE insulation), both belonging to the low voltage power cable group 0.6/1kV according to TCVN 5935-1 (equivalent to IEC 60502-1).

- CVV cable uses PVC (Polyvinyl Chloride) as insulation layer. This material operates stably at maximum 70°C and withstands short-circuit maximum at 160°C. CVV cable is mainly used in residential electrical systems, offices, and commercial areas, where load is stable and environmental conditions are standard.

- CXV cable uses XLPE (Cross-linked Polyethylene) with higher heat resistance capability (90°C) and maximum short-circuit temperature at 250°C. Thanks to this superior heat resistance, CXV is prioritized in industrial plants, underground electrical systems or areas with large loads, where high electrical durability and better thermal safety are required.

Overall, PVC offers cost advantages and easy installation, while XLPE excels in thermal durability, lifespan, and overload resistance.

Quick comparison table between CVV and CXV cables

| Parameter | CVV Cable | CXV Cable |

|---|---|---|

| Insulation material | PVC | XLPE |

| Maximum continuous operating temperature | 70°C | 90°C |

| Maximum short-circuit temperature | 160°C | 250°C |

| Applied standards | IEC 60502-1/ TCVN 5935-1; IEC 60228/TCVN 6612; TCVN 5933; IEC 60227/TCVN 6610 | IEC 60228/ TCVN 6612; IEC 60502-1/ TCVN 5935-1; TCVN 5933 |

| Rated voltage | 300/500V – 0.6/1kV | 0.6/1kV |

| Main applications | Residential, offices | Industrial, underground electrical |

Learn more: To better understand the technical differences and how to choose between the two cable types, you can refer to the in-depth article: Distinguishing CVV and CXV

3. Guide to selecting appropriate 4-cores wire cross-section

Selecting the cable cross-section appropriate to actual load capacity determines both safety and economic efficiency.

Nominal cross-sectional area is the size of the electrical conductor's cross-section. This parameter is measured in mm² and determines the cable's current carrying capacity. Choosing the wrong cross-section leads to serious consequences.

Too small cross-section causes overheating and increases fire and explosion risks. Conversely, too large cross-section increases unnecessary costs. Therefore, correct selection helps optimize between safety and economic efficiency.

3.1. Cross-section reference table by application

| Typical applications | Power (380V, 3 phase) | Suggested cross-section (mm²) |

|---|---|---|

| Office lighting | 3–5 kW | 4×2.5 or 4×4 |

| Small central air conditioning | 7–10 kW | 4×6 or 4×10 |

| Medium industrial motors | 15–20 kW | 4×16 |

| Plastic injection machines, CNC machines | 30–40 kW | 4×25 or 4×35 |

| Distribution trunk lines | 50–70 kW | 4×50 |

| Transformer stations | >100 kW | 4×70, 4×95 and above |

3.2. Important notes on calculation

The above table is for reference only under standard conditions. In practice, multiple factors need to be considered such as cable route length and ambient temperature.

Cable cross-section selection must be calculated in detail and requires consultation from licensed electrical engineers.

4. Frequently asked questions about 4-cores wire

Below are common questions about 4-cores wire that Ngoc Lan Cable's technical team frequently receives.

4.1. Can 4-cores cable replace 3-core wire?

It can replace 3-core wire but it's not optimal. 4-cores cable is designed for 3-phase 1 neutral systems with L1-L2-L3-N structure. If using 4-cores cable to replace a system that only needs 3 cores (without neutral), it will cause cost waste and non-compliance with design. For this reason, the correct cable type should be selected according to system requirements.

4.2. How to distinguish CVV and CXV cables with the naked eye?

They can be distinguished with the naked eye through color. Typically, XLPE insulation will have natural color (clear white) and PVC insulation will have various colors like blue, red, black, yellow.

In case XLPE insulation has black color, the cable type can only be identified through the product code on the cable sheath (clearly marked CVV or CXV) or quality certification from the manufacturer for confirmation.

4.3. Is a separate grounding wire needed when using 4-cores cable?

Yes, a separate protective earth (PE) wire is still needed. 4-cores cable only includes 3 phases and neutral (N).

5. Selecting the right 4-cores wire: The decisive factor for system safety

From structure to technical standards, 4-cores wire is an indispensable component in modern 3-phase electrical systems. Understanding the role of each material layer, which TCVN/IEC standards are applied, and how to select the appropriate cross-section helps ensure maximum safety, performance, and electrical durability.

Key points to understand:

- What is 4-cores wire? Structure consists of copper conductor, insulation layer (PVC or XLPE) and outer sheath, comprising 3 phase wires and 1 neutral wire (L1–L2–L3–N).

- Classification: 2 common types are CVV (PVC) and CXV (XLPE), differing in heat resistance capability and application environment.

- Applications & selection: CVV cable is suitable for residential use, CXV is used for industrial and underground electrical systems; cross-section selection needs to be calculated based on load capacity, cable length, and ambient temperature conditions.

The technical content in this article is referenced from TCVN, IEC standards and ISO/IEC 17025 testing laboratories to provide accurate and objective information.

Understanding correctly – selecting correctly 4-cores wire is the foundation of electrical safety and long-term operational efficiency for all projects.

VN

VN