XLPE is frequently mentioned in both the plastics industry in general and the electrical cable industry in particular. However, many people are still unfamiliar with this term. This article will help you understand the concept of XLPE and its characteristics and applications in electrical cable manufacturing.

1. What is XLPE?

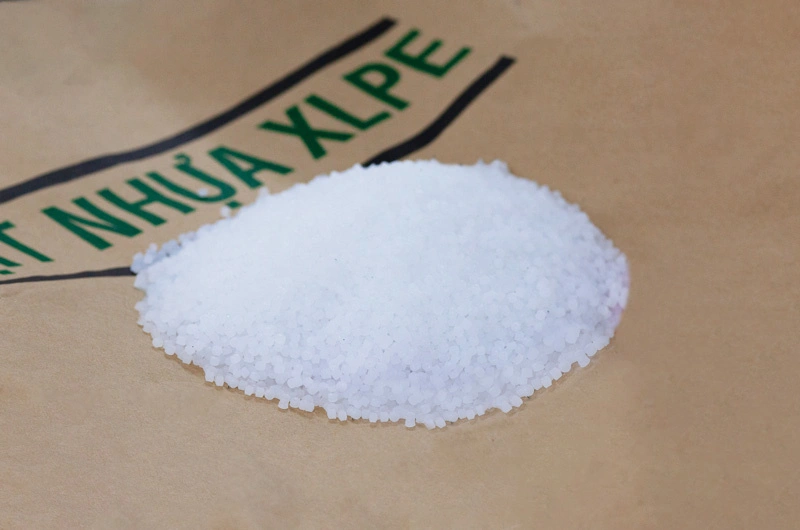

XLPE (also known as XPE or PEX) stands for Cross-linked Polyethylene, a type of polyethylene that has been processed to create cross-links between polymer molecules. This cross-linking of polyethylene creates a mesh-like structure that can resist deformation at very high temperatures.

In simpler terms, XLPE is a type of polyethylene containing organic peroxides. Under high temperature and pressure conditions, combined with inert gas, the peroxide chemically reacts with polyethylene to form XLPE plastic.

2. Characteristics of XLPE

XLPE exhibits several outstanding characteristics:

- Ability to withstand temperature without deformation at extremely high or low temperatures for extended periods

- High insulation resistance, increasing safety and minimizing risk of electrical leakage

- Excellent water resistance and impact resistance

- Resistance to corrosion from many chemicals and corrosive agents

- Does not emit toxic gases (halogen gases) during fire incidents

- Some XLPE types offer oil resistance through special additives and cross-linking process adjustment.

3. Comparison of XLPE with PVC and PE

Before comparing XLPE’s properties with PVC or PE, let’s understand some characteristics of PVC and PE with Ngoc Lan Cable:

Based on these properties, we can make several observations:

- Insulation resistance: XLPE has very high insulation resistance ensuring electrical safety. PVC has medium insulation resistance, easily degrading at high temperatures. PE has high insulation resistance but lower than XLPE.

- Heat resistance: XLPE withstands much higher temperatures compared to PVC and PE. PVC easily softens and melts at high temperatures.

- Mechanical strength: XLPE has better mechanical strength than PVC and PE, better resisting tensile, compression, bending and impact forces.

- Aging resistance: XLPE has the best aging resistance among the three materials, with minimal impact from UV rays and other environmental factors.

- Processing capability: XLPE is more difficult to process than PVC and PE, requiring more technical requirements and specialized equipment.

Thus, XLPE demonstrates superior advantages in terms of electrical insulation, thermal durability, mechanical properties, and aging resistance. However, it comes with a higher cost compared to PVC and PE. PVC offers lower costs and easier processing but has lower overall performance than XLPE. PE occupies a middle position, with costs and performance between XLPE and PVC. Therefore, the choice of material depends on specific application requirements, cost considerations, and durability needs.

4. Applications of XLPE in electrical cables

With its outstanding characteristics, XLPE plays a crucial role in electrical cable manufacturing. Particularly in harsh environments like underground or underwater installations, where cables must withstand significant moisture, temperature, and pressure impacts. Therefore, XLPE is an ideal choice for primary insulation in medium-voltage underground cables, low-voltage underground cables such as CXV/DATA, CXV/S, AXV/SWA…

Additionally, XLPE is used as insulation for various types of metering cables, aluminum twisted cables, low-voltage cables… serving construction projects and other industrial sectors.

5. Guidelines for selecting XLPE insulated cables

Understanding the following considerations will help you choose quality and safe XLPE insulated cables for your needs:

- Select cables with rated voltage greater than or equal to the operating voltage of your electrical system

- Choose conductor cross-sections appropriate for the rated current and power consumption of the equipment

- Select cables with quality certifications that comply with national or international standards such as TCVN, IEC…

- Choose reputable manufacturers with clear product origin to avoid counterfeit products

- Carefully inspect the product including insulation layer, labels, and cable surface for any damage or peeling.

Understanding the concept, characteristics, and applications of XLPE in the electrical cable industry makes it easier to select appropriate electrical cables for specific uses, especially for electricians. If you have any additional useful information about XLPE, please share it with us and other readers for reference.

VN

VN