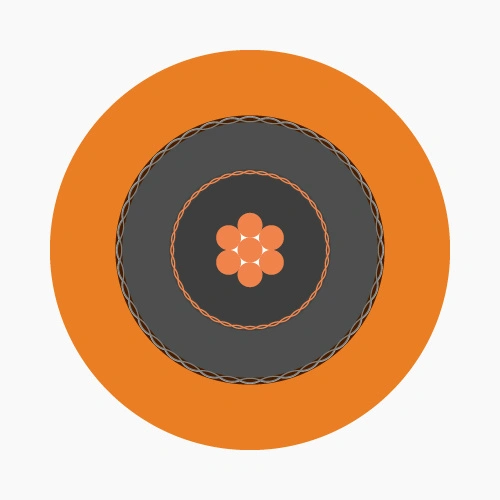

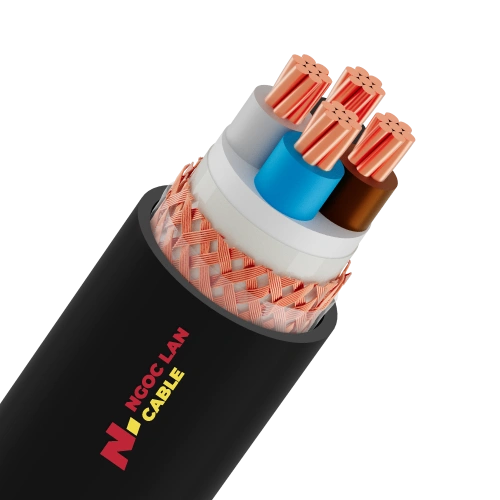

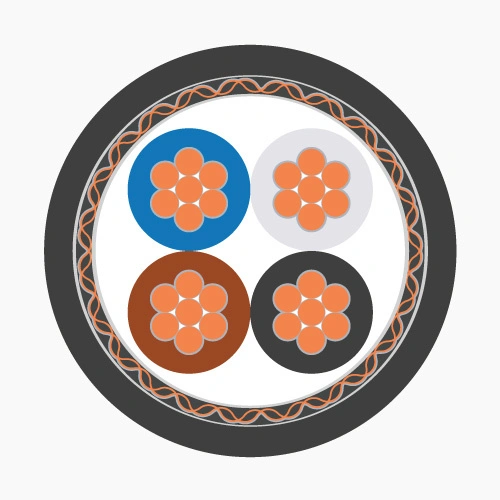

Low Voltage Cables

Low Voltage Cables

Low Voltage Cables

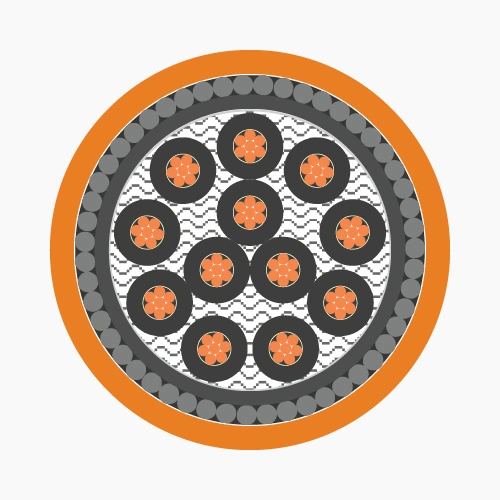

Control Cables

Control Cables

Low Voltage Cables

Fire prevention and protection systems (FPPS) require cables that meet proper technical standards, especially related to fire-resistant cables (FR) and flame-retardant cables (FRT). Therefore, understanding the application objectives of these two cable types will help optimize costs and operational efficiency of electrical systems.

This article will clarify the differences, related standards, and selection process according to Bill of Quantities (BOQ) to help you make appropriate choices for your project.

Important point: Flame-retardant cables do not maintain power supply when fire occurs. The electrical circuit will stop operating when encountering fire. The main advantage is preventing fire from spreading to other areas. This helps limit damage and protect human lives.

Note: LSZH is typically required in enclosed areas or crowded spaces according to local fire safety regulations; cross-check before finalizing design.

With the above recommendations, you can now determine the appropriate cable type for each system in the project. However, to prepare detailed BOQ (Bill of Quantities) and cross-reference with suppliers, engineers need specific technical parameters such as available cross-sections, electrical parameters, and product codes according to each standard. Therefore, referencing product catalogues will support the design process more effectively.

Step 1: Determine usage requirements

Fire-resistant cable selection starts with system function analysis. Emergency evacuation systems require fire-resistant cables to maintain operation. Conventional distribution systems can use flame-retardant cables to save costs.

Step 2: Evaluate installation area

Enclosed spaces or crowded areas mandatorily require LSZH cable sheath. Depending on fire safety standards in each area, choose cable sheath materials appropriate to that area's regulations. Thoroughly checking fire safety regulations before design is essential.

Step 3: Calculate electrical parameters

Low voltage fire-resistant cables typically have voltage levels of 0.6/1kV. Wire cross-section is selected based on design load current and allowable voltage drop. Accurate calculation prevents overload and ensures system efficiency.

Step 4: Check technical standards

Tender documents typically specify applicable standards clearly. Testing according to production lots ensures consistent quality for the entire supplied quantity. Test results must be from testing laboratories with ISO 17025 certification.

Step 5: Prepare acceptance documentation

The following documents need to be prepared for the acceptance process:

Consequences of wrong selection:

3 principles to remember:

- Meet acceptance requirements: Accurately distinguish fire-resistant cables from flame-retardant cables according to IEC 60331/60332 and BS 6387 standards to avoid errors in technical documentation.

- Use LSZH materials appropriately: Know when to apply cables with LSZH sheath (Low Smoke, Zero Halogen), avoiding unnecessary wasteful use.

- Consulting according to BOQ: Guide selection of appropriate cable types based on specific technical requirements of each system in the project.

- Cost control: Avoid using fire-resistant cables when unnecessary.

1. Overview of 2 types of Fire-Resistant and Flame-Retardant cables

Before diving into detailed comparisons, understanding the basic characteristics of each cable type will help you grasp the operating principles and suitable applications. Since the safety objectives differ, the standards applied to fire-resistant and flame-retardant cables also vary.1.1. Fire-Resistant cables

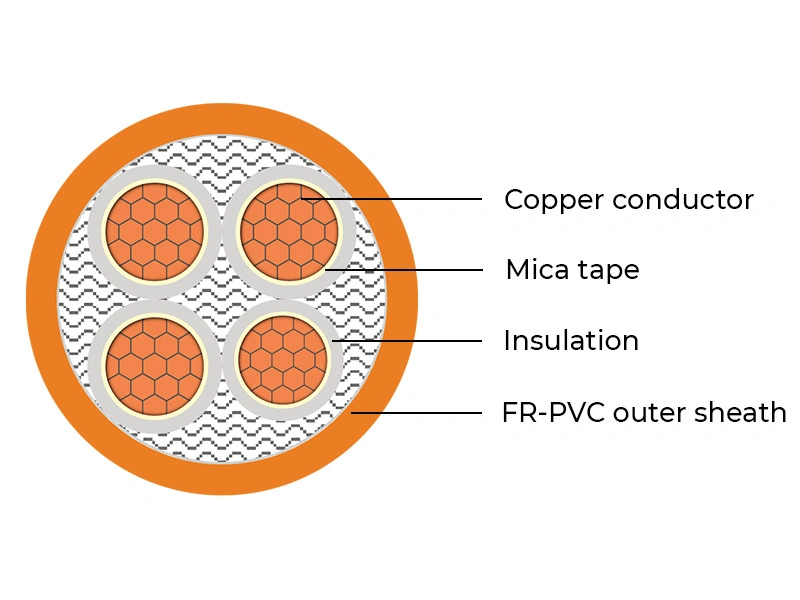

Fire-resistant cables are designed to maintain electrical circuits when the cable is on fire. The structure typically includes mica tape wrapped around the conductor to protect the electrical core. Mica tape can withstand temperatures from 750-950°C depending on the manufacturing method. Some product lines can reach the threshold of 1000°C. Therefore, the electrical circuit continues to operate stably to transmit signals and supply power to fire prevention and fighting equipment.1.2. Flame-Retardant cables

In contrast, flame-retardant cables (FRT - Flame-Retardant) have a completely different purpose from fire-resistant cables. This type of cable is designed to limit flame propagation.Important point: Flame-retardant cables do not maintain power supply when fire occurs. The electrical circuit will stop operating when encountering fire. The main advantage is preventing fire from spreading to other areas. This helps limit damage and protect human lives.

In-depth reference materials:

2. Applications and recommendations when using 2 types of cables

Categorizing applications according to each intended use will help you accurately determine the type of cable needed for each installation area in the project.2.1. Applications for fire prevention and fighting systems (Priority: Fire-Resistant cables)

Systems that need to operate when fire occurs to extend evacuation time include:-

- Fire alarm systems

- PA/VA (Public Address/Voice Alarm systems - evacuation guidance during emergencies)

- Emergency lighting

- Pressurization fans

- Fire pumps

- Emergency elevators

2.2. Applications for civilian systems (Priority: Flame-retardant cables)

Conventional systems such as daily-use equipment in offices, residential buildings... operate differently from evacuation systems. Since these devices do not need to maintain operation when fire incidents occur, the main purpose is to prevent fire spread originating from these devices rather than maintaining power supply. Therefore, flame-retardant sheathed cables become the optimal choice in terms of cost.2.3. Recommendations by installation area

The table below provides cable type suggestions for each specific application, evaluated by priority level. These suggestions help engineers select appropriate cable types for each installation area.| Area | Protection objective | Recommended cable type |

|---|---|---|

| Fire control center | Maintain operation during fire | Fire-resistant cable with mica tape + XLPE |

| Fire pump area | Continuous power supply for pumps | Fire-resistant cable with LSZH sheath |

| Offices and residential areas | Limit flame propagation | Flame-retardant cable with PVC or LSZH sheath |

| Elevators and enclosed basements | Reduce toxic smoke + maintain circuits | Fire-resistant cable with mandatory LSZH sheath |

3. Detailed comparison of fire-resistant and flame-retardant cables

To clearly understand the differences in functionality and applications, the following comparative criteria help you make a more comprehensive evaluation:3.1. Main functions

- FR: Maintain electrical circuits during fire and operate fire alarm equipment.

- FRT: Limit flame propagation to reduce the risk of fire outbreak.

3.2. Structure

- FR: Mica tape wrapped around conductor, heat-resistant XLPE insulation, PVC/LSZH sheath; LSZH preferred for enclosed spaces.

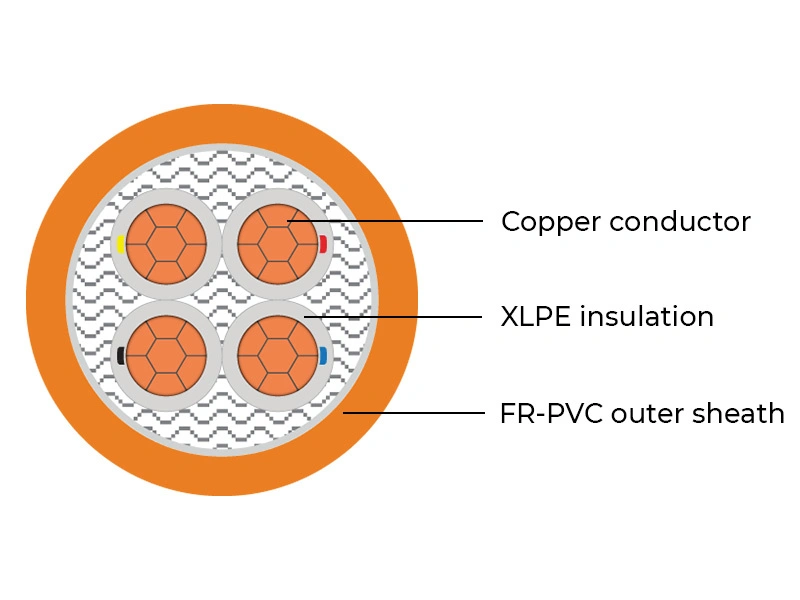

- FRT: Flame-retardant compounds in sheath/insulation, no specialized circuit protection layer like mica.

3.3. Ability to maintain operation during fire (Mechanism explanation)

- FR (Fire-Resistant) maintains circuit integrity due to the mica tape layer creating a thermal barrier around the conductor, so even if the sheath burns, the conductor does not short-circuit or break prematurely. The result is that signal/power supply is not interrupted.

- FRT (Flame-Retardant) does not maintain circuits when fire acts long enough, the insulation layer is gradually damaged and the circuit may stop operating, but the material will limit flame spread to other areas.

3.4. Main standards

- FR: IEC 60331 (circuit integrity), BS 6387 (C/W/Z).

- FRT: IEC 60332-1 (single cable), IEC 60332-3 (bundled cables).

- LSZH related: IEC 61034 (smoke density), IEC 60754 (acid gas)..

3.5. Cost and installation

FR is typically more expensive than FRT due to materials and stringent testing; supply time may be longer. Therefore, clear system zoning is needed to use FR only where truly mandatory.4. Cable selection guide in 5 steps

Cable selection must follow standard procedures to ensure proper intended use and cost optimization:Step 1: Determine usage requirements

Fire-resistant cable selection starts with system function analysis. Emergency evacuation systems require fire-resistant cables to maintain operation. Conventional distribution systems can use flame-retardant cables to save costs.

Step 2: Evaluate installation area

Enclosed spaces or crowded areas mandatorily require LSZH cable sheath. Depending on fire safety standards in each area, choose cable sheath materials appropriate to that area's regulations. Thoroughly checking fire safety regulations before design is essential.

Step 3: Calculate electrical parameters

Low voltage fire-resistant cables typically have voltage levels of 0.6/1kV. Wire cross-section is selected based on design load current and allowable voltage drop. Accurate calculation prevents overload and ensures system efficiency.

Step 4: Check technical standards

Tender documents typically specify applicable standards clearly. Testing according to production lots ensures consistent quality for the entire supplied quantity. Test results must be from testing laboratories with ISO 17025 certification.

Step 5: Prepare acceptance documentation

The following documents need to be prepared for the acceptance process:

- Certificate of Analysis (COA) confirming technical parameters from the manufacturer.

- Test reports providing actual test results for each cable lot.

- Project acceptance requires complete documentation proving product quality.

Consequences of wrong selection:

- Using FRT for systems requiring circuit maintenance: risk of signal/power loss during fire, regulation violation, acceptance rejection, requiring complete route replacement.

- Using FR where only FRT is needed: cost increases 2-4 times, budget waste and unnecessary construction load increase.

5. Standards and testing methods

To quickly cross-reference technical requirements, the information below summarizes the main standards and scope of application:- IEC 60331: Maintain circuit at 750°C for specified duration (e.g., 90 minutes) with rated voltage (applies to FR).

- BS 6387 C/W/Z: has different test levels: 650°C, 750°C, 950°C for 3 hours, with additional conditions such as water spray (W) and mechanical impact (Z). Applied to FR with critical equipment.

- IEC 60332-1/-3: Burn at specified angle/height, evaluate self-extinguishing capability and flame height limit (applies to FRT).

- IEC 61034: Measure smoke density.

- IEC 60754: Evaluate acid gas/corrosion; related to halogen-free/LSZH materials.

6. Frequently asked questions about fire-resistant and flame-retardant cables

The section below summarizes common questions arising when selecting these 2 types of cables.6.1. Can flame-retardant cables replace fire-resistant cables if run in steel conduit?

No, because steel conduit only provides mechanical protection, so if the system needs to ensure circuit integrity capability, fire-resistant cables according to IEC 60331/BS 6387 must still be used.6.2. Is LSZH sheath mandatory for FR cables?

Not mandatory. Since LSZH sheath depends on environment/fire safety conditions, it is preferred in enclosed spaces or high population density areas.6.3. Must fire-resistant cables meet all C, W, Z or is only C sufficient?

Only C is sufficient. According to BS 6387, fire-resistant cables are tested under 3 groups of conditions:- C (prolonged fire): maintain electrical circuit at 950°C for 3 hours.

- W (water spray from firefighting): maintain electrical circuit during fire + water spray.

- Z (mechanical impact): maintain electrical circuit during fire + mechanical impact.

- Minimum requirement: usually only need to pass test C (continuous burning at 950°C/3h) to be considered fire-resistant cable.

- However, in many technical standards, high-rise projects, airports, hospitals, investors will require cables to meet all CWZ to ensure cables continue operating.

7. Project application: Summary and technical support

Through the above 6 sections, you have understood the differences between fire-resistant and flame-retardant cables, applicable standards and the 5-step selection process. Now, let's summarize the key points for immediate application to your project.3 principles to remember:

- System zoning: Only use fire-resistant cables (2-4 times more expensive) for systems requiring circuit maintenance during fire such as fire alarms, PA, fire pumps, emergency elevators according to IEC 60331/BS 6387; civilian systems should use flame-retardant cables to optimize costs.

- Prioritize LSZH sheath for enclosed spaces: Areas with high population density or limited ventilation need LSZH sheath to reduce toxic smoke, extending safe evacuation time.

- Prepare documentation from the start: Collect test reports from ISO/IEC 17025 laboratories immediately upon receiving goods to avoid rejection of acceptance documents and ensure schedule compliance.

VN

VN