Fires pose a constant threat to residential and industrial buildings, with many serious incidents originating from electrical short circuits caused by substandard wiring. Fire-resistant power cables have emerged as an effective solution to protect assets and human lives. But what exactly are fire-resistant cables? Let’s explore their structure, characteristics, and applications.

1. Introduction to fire-resistant power cables

1.1 What are fire-resistant power cables?

Fire-resistant cables (also known as fire resistant cables) are power cables designed with special properties to resist burning, reduce flame spread, and maintain circuit integrity when exposed to high temperatures for a certain duration. This crucial feature ensures vital electrical equipment like emergency lighting and fire alarm systems continue to receive power during a fire event.

1.2 Structure

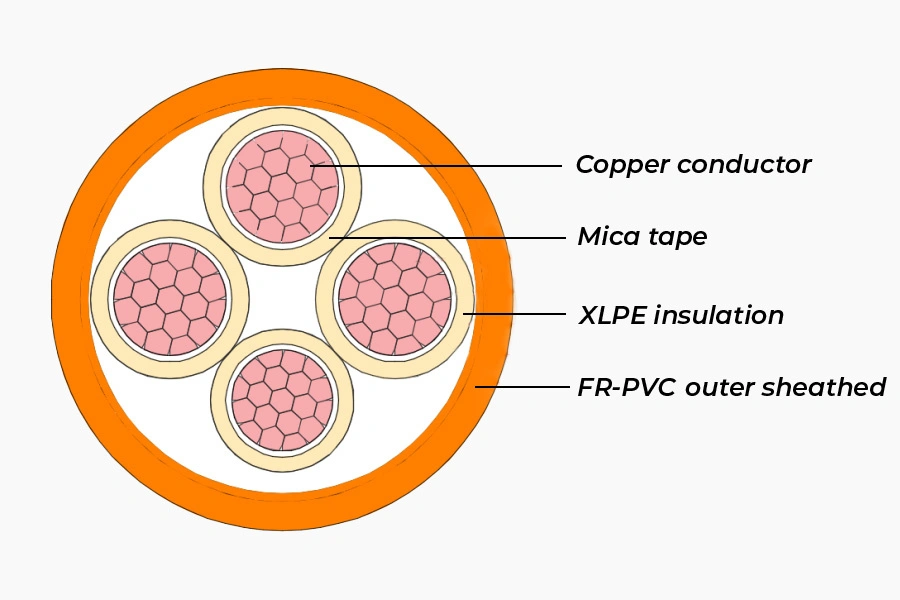

A typical fire-resistant power cable consists of 4 main components:

- Conductor: Usually made of copper which has excellent electrical conductivity and heat resistance.

- Fire barrier: Commonly uses mica tape.

- Insulation: Often uses XLPE (Cross-linked polyethylene) to protect and isolate the copper conductor.

- Outer sheath: Typically made of LSZH (Low Smoke Zero Halogen) or FR-PVC.

1.3 Technical standards

Fire-resistant cables must meet stringent quality and safety standards. The cables should fulfill the following requirements:

- Withstand temperatures of 650-950°C for 15 to 180 minutes.

- Not produce toxic gases during combustion.

- Prevent flame propagation and self-extinguish when the ignition source is removed.

- Maintain circuit integrity for at least 30 minutes at 950°C.

Some key standards for fire-resistant cables include:

- IEC 60331: Requires the cable to withstand burning at 750°C for a minimum of 90 minutes.

- CNS 11174: Mandates the fire-resistant cable endure burning at 840°C for 30 minutes.

- BS 6387 Category A: Necessitates the fire-resistant cable to withstand 650°C for 3 hours.

- BS 6387 Category B: Requires the fire-resistant cable to tolerate 750°C for 3 hours.

- BS 6387 Category C: Demands the fire-resistant cable to resist 950°C for 3 hours.

- BS 6387 Category W: Requires the fire-resistant cable to withstand 650°C for 15 minutes with water spray, followed by an additional 15 minutes of water exposure.

- BS 6387 Category X: Mandates the fire-resistant cable to endure 650°C for 15 minutes with mechanical impact.

- BS 6387 Category Y: Necessitates the fire-resistant cable to tolerate 750°C for 15 minutes with mechanical impact.

- BS 6387 Category Z: Requires the fire-resistant cable to resist 950°C for 15 minutes with mechanical impact.

2. Classification of fire-resistant power cables

Fire-resistant power cables are commonly divided into 2 main types:

- General fire-resistant cables (with FR-PVC or FR-CL sheath): Typically has a structure of Cu/Mica/XLPE/FR-PVC (some cables may have additional DSTA armor – 2 layers of steel tape). This is the most popular choice for regular projects that meet minimum fire resistance requirements.

- Special fire-resistant cables (with LSZH sheath): Usually constructed as Cu/Mica/XLPE/LSZH (some cables may have additional DSTA armor – 2 layers of steel tape) with excellent heat resistance. The halogen-free LSZH sheath minimizes toxic smoke emission during a fire. These are used in high safety applications like shopping centers, high-rise buildings, apartments, airports, etc.

3. Comparing fire-resistant cables to regular power cables

Designed with features to prevent electrical fires, fire-resistant cables offer several key advantages over standard power cables:

4. Practical applications of fire-resistant power cables

Fire-resistant cables are widely used in various residential and industrial projects, such as:

- High-rise buildings: Install fire-resistant cables for fire alarm systems, emergency lighting, evacuation elevators, etc.

- Shopping malls, cinemas, hospitals: Use fire-resistant cables for automatic sprinkler systems, smoke detectors, etc.

- Factories, warehouses, especially those storing flammable goods: Employ fire-resistant cables for electrical systems, lighting, sprinklers, fire alarms, etc.

- Tunnels, subway stations: Install fire-resistant cables to ensure power supply for ventilation fans, drainage pumps, fire detection systems, etc.

Equipping a building with fire-resistant cables not only meets fire safety regulations but also provides peace of mind for occupants and minimizes economic losses in the event of a fire. Particularly in chemical plants or warehouses with combustible materials, fire-resistant cables help prevent the fire from spreading, extending the precious time window for evacuation and firefighting efforts.

5. How to select the right fire-resistant power cable

To choose the most suitable fire-resistant cable for your project, consider the following factors:

- Pick the appropriate conductor material and cross-section: Opt for fire-resistant cables with copper conductors and cross-sections of 1.0 mm² or larger. This ensures the core won’t easily break due to uneven heat distribution, which could lead to loss of conductivity.

- Choose the right fire-resistant mica tape: Prefer synthetic mica tapes over phlogopite (magnesium mica) for better quality and cable stability.

- Select the proper insulation material: PVC mainly consists of polyvinyl chloride and CaCO3. When burned, it produces a mixture of solid residue that adheres to the mica tape, creating stress that may damage the tape. In contrast, XLPE and PE are pure hydrocarbons without fillers. They decompose into CO2 and water vapor when burned, leaving only a small amount of solid residue on the mica, which has less impact. Therefore, while PVC is acceptable, PE and XLPE are superior insulation choices.

- Buy from reputable brands: Choose cables with clear origins and international quality certifications like ISO and BS.

Additionally, consulting experts or technical advisors can help you make informed decisions and optimize your fire-resistant cable investment. Always carefully review the technical specifications for each cable type to understand its parameters and installation requirements.

6. Frequently asked questions (FAQs) about fire-resistant power cables

6.1 What misconceptions do people often have about fire-resistant cables?

Many people mistakenly believe that fire-resistant cables are completely fireproof and can be used under any conditions. In reality, “fire-resistant” does not mean the cable cannot burn. Rather, it has properties that make it difficult to ignite and limit flame spread for a certain period. If exposed to a strong, prolonged fire source, fire-resistant cables will eventually fail like regular cables. Therefore, regular maintenance and timely replacement of fire-resistant cables are crucial for ensuring fire safety.

6.2 What does LSZH mean in the context of fire-resistant cables?

LSZH stands for Low Smoke Zero Halogen. It is currently the highest standard for fire-resistant cables, requiring minimal smoke emission and no halogens that could cause suffocation, such as chlorine or fluorine.

6.3 Should fire-resistant cables be used throughout the entire building or only in critical areas?

From a safety perspective, installing fire-resistant cables in all electrical systems is ideal. However, this can be quite costly. Experts recommend using fire-resistant cables in crucial areas like emergency lighting, fire alarms, automatic sprinklers, and critical infrastructure. For less critical spaces like offices and stairwells, regular power cables may be sufficient.

7. Conclusion

With the information provided, you should now have a clearer understanding of the structure, classification, and applications of fire-resistant power cables. More importantly, you can appreciate their vital role in protecting property and human lives by preventing catastrophic fires.

This article aims to provide a basic yet comprehensive overview of fire-resistant cables for electrical engineering students, novice electrical engineers, and even non-professionals. Armed with this knowledge, you’ll be better equipped to select the most suitable products for your projects.

VN

VN