Cable shielding acts as a protective barrier that safeguards signals from electromagnetic interference (also known as electrical noise – EMI). EMI is the leading cause of signal interference issues, reducing transmission quality, causing data errors, damaging electronic equipment and electrical systems.

This article provides detailed analysis to help you select the right type of cable:

- Detailed structure of shielded cables with 4 main components

- Comparison of foil shields and braid shields in terms of mechanism and effectiveness

- 4 criteria for selecting cables suitable for specific environments

Join Ngoc Lan Cable in exploring detailed information about cable shielding, helping you make appropriate cable selections for your electrical system projects.

1. Why is cable shielding important?

Electrical signals in transmission systems are frequently affected by electromagnetic interference (EMI) and radio frequency interference (RFI). These are electrical noise phenomena originating from high-power motors, inverters and switching equipment.

Control signals typically have very low voltage, making them highly susceptible to environmental interference that can cause transmitted data to become distorted and inaccurate. A typical example is PLC systems (which operate based on programming algorithms to read and process data from sensors) that can easily receive incorrect values due to signal interference.

Cable shielding functions as a Faraday cage (a hollow conductor in which the electric field at all points inside is zero) surrounding the conductor cores. When electromagnetic waves contact this metallic layer, they create induced current on the surface of the shielding layer. This current is conducted to ground instead of penetrating inside the cable, thereby preventing electromagnetic interference from entering the internal signals.

2. Structure of shielded cable

To understand the operating mechanism clearly, analyzing the shielded cable structure is necessary. A shielded cable consists of 4 main components.

2.1. Conductor

The conductor is the main component responsible for signal transmission, typically made from copper to ensure high electrical conductivity. In humid environments or those with chemicals, tin-plated copper is used.

In terms of structure, the conductor can be solid or stranded. Stranded conductors provide greater flexibility, suitable for applications requiring frequent bending.

2.2. Insulation

Each conductor is wrapped by an insulation made from PVC or XLPE. The primary function is to prevent short circuits between conductors.

PVC is a common material with low cost and good insulation capability at temperatures below 70°C. XLPE is a more premium insulation material with heat resistance up to 90°C, exceeding PVC by approximately 30% in insulation properties.

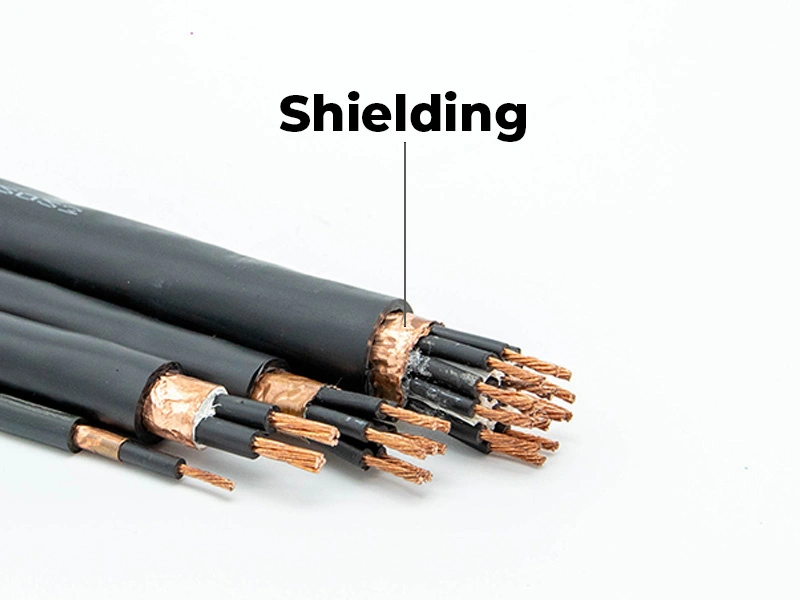

2.3. Shielding (Screen)

The shielding is typically made from thin aluminum foil or braided copper mesh, placed around the bundle of insulated cores. This is the critical layer that distinguishes shielded cables from ordinary cables, functioning as a protective barrier for signals.

2.4. Outer sheath

The outermost sheath layer is responsible for protecting all internal cable components, providing resistance against physical impact, chemicals, moisture and UV rays. PVC is a suitable and common material for the outer sheath with good abrasion resistance.

In construction projects with strict fire prevention requirements, LSZH sheath is commonly used. When burned, LSZH produces very little smoke and does not emit toxic gases containing halogens. At Ngoc Lan Cable, we provide a complete range of cables with LSZH sheath meeting IEC 60332 standards.

3. Common types of cable shielding

The effectiveness of shielded cables depends heavily on the types of shielding layers used. Common types include foil shields, braid shields, and combination shields.

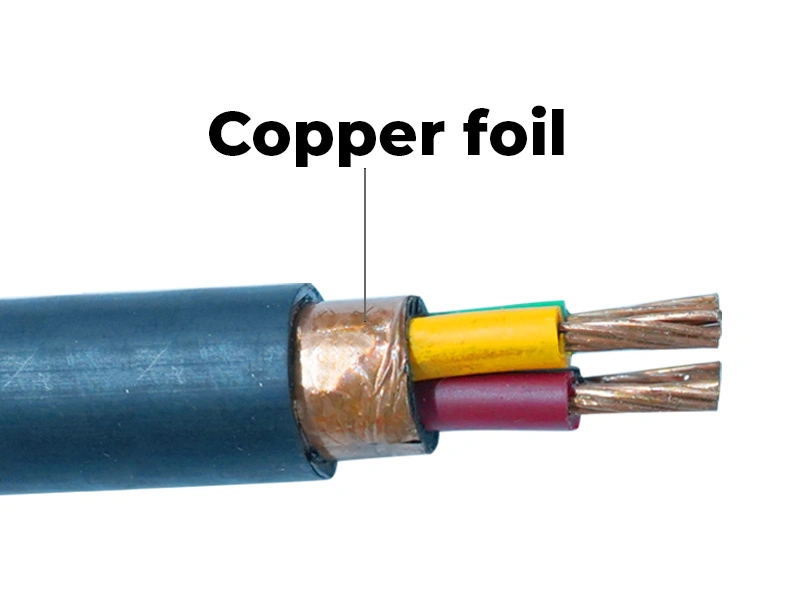

3.1. Foil shield

Foil shields use thin aluminum or copper foil with thickness ranging from 0.05 – 0.1mm coated with polyester (PET). This structure creates 100% surface coverage of the cable core, completely blocking high-frequency interference waves above 15 KHz from penetrating the conductor core.

Therefore, foil shields are suitable for environments with digital electronic equipment and high-speed switching devices. The main advantages are low cost and easy grounding through drain wires. However, poor flexibility makes foil shields prone to tearing when bent repeatedly.

For these reasons, foil shields should only be used for fixed installation applications in conduit.

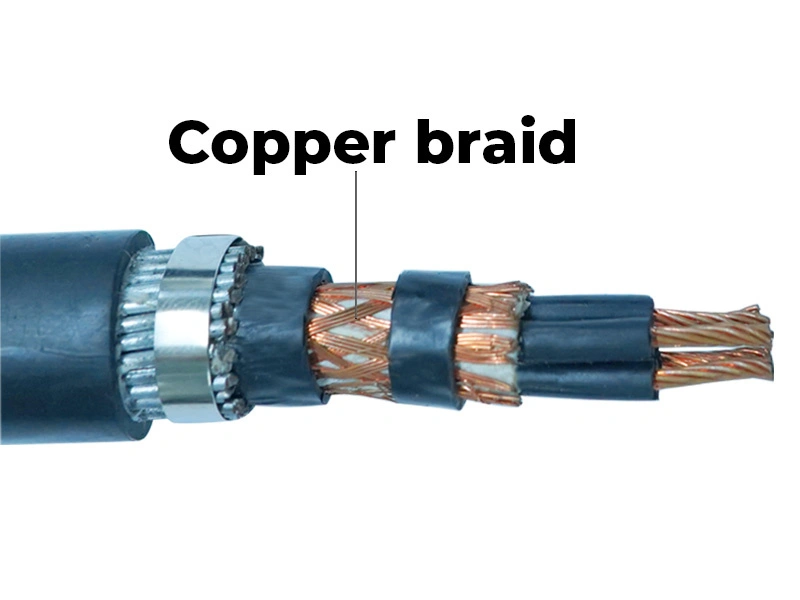

3.2. Braid shield

Braid shields are formed from copper or tin-plated copper wires with wire diameter ranging from 0.1 – 0.2 mm woven crosswise into a mesh layer surrounding the conductor core. This structure provides better mechanical durability compared to foil shields and effectively protects against low-frequency interference below 15 KHz.

Low-frequency interference commonly appears in factory environments with motors and inverters. Braid shields can withstand thousands of bending cycles without damage, making them suitable for mobile applications such as industrial robot arms.

The disadvantages are higher cost and heavier weight than foil shields. Coverage only reaches 70-95% compared to foil shields.

3.3. Combination shield (foil & braid shield)

Combination shields include an inner foil shield layer and an outer braid shield layer. This structure provides optimal protection effectiveness across the entire frequency range.

This cable type is used in environments with extremely high EMI levels. Typical examples include metallurgical plants, broadcasting stations and large data centers, where both high and low-frequency interference occur simultaneously.

Combination shields cost more than the other two types and should be considered when the environment truly requires maximum protection level.

4. Comparison table of advantages and disadvantages of foil shield and braid shield

Comparing foil shields and braid shields is an important technical decision to help you make the appropriate choice. The table below summarizes and compares the main characteristics.

| Criteria | Foil shield | Braid shield |

|---|---|---|

| Frequency effectiveness | Excellent at high frequencies (>15 KHz) | Excellent at low frequencies (<15 KHz) |

| Độ che phủ | 100% | 70% – 95% |

| Durability & Flexibility | Poor, tears easily when bent repeatedly | Excellent, durable, highly flexible |

| Cost | Low | High |

| Ease of connection | More difficult (requires drain wire) | Easier (direct soldering/clamping) |

As the comparison table shows, no type is perfect for all cases. For environments with high-frequency interference and fixed cable installation, foil shields are the economical choice. For cables that must move frequently or environments with low-frequency interference, using braid shields is the more optimal choice.

In many projects at automotive and food manufacturing plants, proper analysis of interference sources has helped reduce the number of signal interference-related incidents by 40-60%. The experts at Ngoc Lan Cable are always ready to consult on appropriate cable solutions for each specific environment.

5. Guide to 4 criteria for selecting appropriate shielded cables

Selecting the right shielded cable requires careful consideration of technical factors. Below are 4 important criteria you need to consider.

5.1. Criterion 1: Analyze the interference environment

The initial step is to identify the main interference sources in the environment to select the correct type of shield:

Low-frequency interference (<15 KHz):

- Source: High-power motors, inverters, electric welding machines, mechanical switching equipment

- Characteristics: Creates strong, slowly varying magnetic fields

- Solution: Use braid shields

High-frequency interference (>15 KHz):

- Source: Radio equipment, digital equipment, switching power supplies

- Characteristics: Electromagnetic waves propagating through space

- Solution: Use foil shields with 100% coverage

Mixed interference:

- Environment: Metallurgical plants, complex metal processing workshops

- Solution: Use combination shields

5.2. Criterion 2: Evaluate mechanical requirements and flexibility

You need to consider whether the cable will be installed in a fixed position or must move and bend continuously, as this directly affects the cable flexibility required.

Static applications (fixed cables):

Cables are installed from electrical cabinets to fixed machinery. They run through conduit or on cable trays and do not need to move throughout the operating process. Therefore, foil shields are the appropriate choice.

Dynamic applications (moving cables):

Cables must bend continuously in applications such as robot arms. Mobile equipment on rails or cable chains requires cables that can withstand thousands of bending cycles. For these reasons, braid shields are the appropriate choice for durability.

5.3. Criterion 3: Evaluate grounding methods

The effectiveness of cable shielding depends entirely on proper grounding of the shielded cable. Without grounding, the shield layer becomes an antenna that receives interference, increasing system noise.

Single-end grounding:

Single-end grounding is commonly used in cases involving low frequencies, where induced interference can create ground loop currents if grounded at multiple points.

Double-end grounding:

Double-end grounding is used for special cases such as long cables or environments with very strong interference, where grounding at both ends helps protect against electromagnetic interference more effectively. However, the design must be meticulous to avoid ground loop interference.

5.4. Criterion 4: Read and understand cable technical specifications

Finally, you need to know how to read and understand the symbols and technical specifications of cables provided by manufacturers to ensure accurate selection.

Shield type symbols on cables:

- CVV/Sa: Cable with aluminum foil shield

- CVV/Sc: Cable with copper foil shield

Other technical specifications requiring attention:

- Number of cores and cross-sectional area (mm²)

- Insulation material (PVC or XLPE)

- Fire resistance standards (if the project requires)

- Voltage rating and operating temperature

Reading specifications correctly helps avoid errors in selecting appropriate wire and cable products for projects.

6. Practical applications: When to use shielded control cables and signal cables?

Regarding practical applications of shielded cables, they are commonly divided into two main types: control cables and signal cables, each serving different purposes.

6.1. Shielded control cables

Shielded control cables are used to transmit low-voltage signals. They are applied in industrial equipment automation such as connecting PLCs, sensors, relays and solenoid valves to form automation systems, serving production lines.

Factory environments typically have many high-power motors and inverters operating. They generate common low-frequency interference, therefore control cables commonly use copper braid shields as the shielding layer, which also provides high mechanical durability.

6.2. Shielded signal cables

Shielded signal cables are used to transmit data, audio and video. The critical point of these cables is ensuring absolute data integrity because digital data is highly sensitive to interference, even a small interference pulse can cause data bit errors.

7. Frequently asked questions about shielded cables

To clarify common technical issues, below are answers to some frequently asked questions about shielded cables that electrical engineers and technicians often raise when designing and installing systems.

7.1. When should shielded cables be used and when should they not?

Shielded cables should be used when the environment has high levels of electromagnetic interference, signals are sensitive, and absolute accuracy is required. This is a mandatory choice for industrial automation systems.

More specifically, you need to use shielded cables in the following cases:

Installation environments with strong interference sources:

- Near high-power motors (above 5kW)

- Areas with inverters, electric welding machines

- Cables running parallel to power cables on the same support rack

Requirements for accuracy and stability of transmitted signals:

- PLC control signals with low voltage (below 24VDC)

- High-speed data such as RS485, Profibus

- Analog signals from measurement sensors (4-20mA, 0-10V)

In cases where the environment has little interference, signals are not sensitive, and cost savings are needed, you can use ordinary cables (UTP).

7.2. Are shielded control cables more expensive than ordinary cables?

Yes, shielded control cables are more expensive than ordinary cables by approximately 30-50%. This additional cost comes from adding the metallic shield layer (foil shield or braid shield) and more complex manufacturing processes.

8. Conclusion

Selecting the appropriate shielded cable is an important technical decision that directly affects the operational stability of the entire system.

Through detailed analysis, there are 3 important points to note:

- Understanding the structure of shielded cables and the importance of cable shielding

- Clearly understanding the differences between foil shields and braid shields to select the correct type

- Mastering the 4 criteria for selecting appropriate shielded cables

For detailed technical consultation and quotations for shielded cables suitable for your project, please contact the experts at Ngoc Lan Cable. We are committed to providing high-quality products that fully meet IEC and TCVN technical standards for your industrial systems.

VN

VN