- Technical analysis of physical mechanisms causing overheating phenomena

- Risk assessment based on national and international safety standards

- Guidelines for selecting appropriate materials to ensure safety

- Diagnostic procedures and technically correct safety handling

Ngoc Lan Cable with experience implementing large projects understands that electrical safety originates from proper material selection and standards compliance from the design phase.

1. Is it normal for electrical wires to be “warm” during use, and how is it different from abnormal “overheating”?

The generation of heat in conductors when electric current flows through them is a completely normal physical phenomenon, known as the Joule effect. To accurately assess safety levels, engineers need to clearly distinguish between “warm” within acceptable limits and “overheating” that signals a malfunction.

Safe operating temperature according to standards

According to TCVN 6610 (equivalent to IEC 60227), PVC insulated electrical wires typically operate safely at conductor temperatures up to 70°C. XLPE insulated wires can withstand higher temperatures, up to 90°C according to TCVN 5935 (IEC 60502-1).

Clear definitions: “Warm” and “Overheating”

- “Warm” is understood as when the wire operates within the temperature threshold permitted by the manufacturer and technical standards. This is a normal and safe condition.

- “Overheating” is when the temperature exceeds this threshold, often accompanied by signs such as plastic sheath softening, burnt smell, or color changes. This is a warning sign that requires immediate attention.

Practical inspection methods

Engineers can use infrared thermal guns to accurately measure the wire surface temperature. If the surface temperature exceeds 60°C for PVC wires or 80°C for XLPE wires, the system should be inspected immediately.

2. Why do electrical wires overheat? Analysis of 7 core technical causes

The phenomenon of electrical wire overheating is not random but results from specific technical errors. The analysis below focuses on each cause:

2.1. Incorrect conductor cross-sectional area selection

This is the most common cause in projects lacking proper technical calculations. The inverse relationship between cross-sectional area and resistance directly determines the amount of heat generated.

Basic formula: S = (ρ.I)/R

- S: Cross-sectional area (mm²)

- ρ: Resistivity of conductor material (Ω.mm²/m)

- I: Current intensity (A)

- R: Conductor resistance (Ω)

When the cross-sectional area is smaller than required, resistance increases significantly, leading to excessive heat generation.

Example: Using 1.5mm² wire for a 20A load instead of 2.5mm² wire increases resistance by nearly 40%, causing serious overheating.

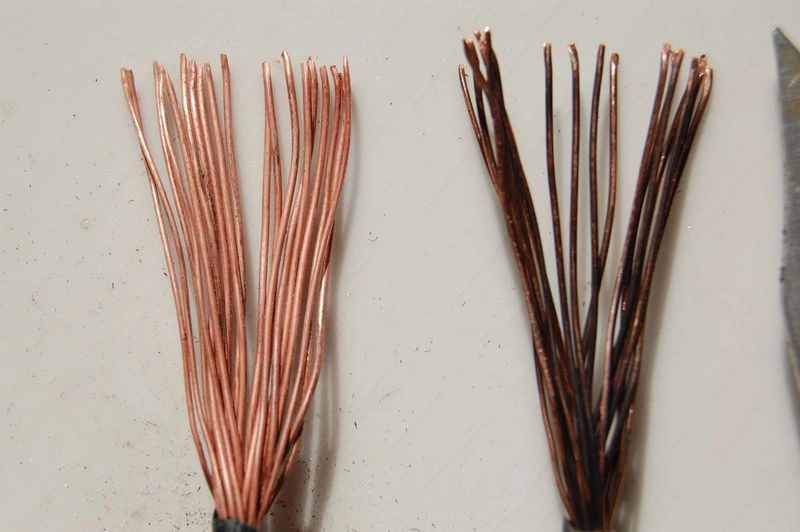

2.2. Substandard conductor material quality

Copper purity is the determining factor for resistivity. Standard copper has a resistivity of approximately 0.017241 Ω.mm²/m at 20°C. Copper with impurities or copper-clad aluminum (CCA) wires have significantly higher resistivity.

Using poor-quality materials easily causes heat generation and reduces the lifespan of electrical conductors.

2.3. Substandard insulation sheath (PVC/XLPE)

Poor-quality insulation sheaths will easily soften and age under heat effects during use. This reduces insulation capability and may cause short circuits and electrical faults.

2.4. Loose connections or improper techniques

Connections are the points with the highest resistance on the wire if not properly handled. Looseness or oxidation at connection points causes severe localized heat generation.

2.5. Electrical system overload

This occurs when the total power consumption of devices exceeds the wire's load-carrying capacity. High current causes the entire conductor to heat up according to the formula P = I²R.

Technical solution: Recalculate the appropriate coincidence factor and reserve factor suitable for each load type.

2.6. Installation environment effects

Installing wires in high-temperature environments, enclosed spaces without heat dissipation, or running multiple wires in the same conduit reduces heat dissipation capability.

2.7. Material aging

Over time, both insulation materials and conductors can degrade due to effects of temperature, humidity, and chemicals. This increases resistance and risk of incidents.

3. What serious consequences does electrical wire overheating cause for projects?

For engineers and contractors, the phenomenon of electrical wire overheating comprehensively affects project efficiency and reputation. Detailed analysis of consequences helps properly assess risk levels and develop appropriate safety and suitable measures.

3.1. Direct and indirect economic losses

Excessive heat generation in electrical wires causes many unexpected costs for projects.

Power loss costs:

- Wastes 5-15% of electrical energy converted to heat

- Increases monthly operating costs

- Reduces overall system efficiency

Repair and replacement costs: When systems overheat, replacing cables, protective equipment, and repairing damage can amount to 30-50% of the original system value. Particularly in completed construction projects, replacement is much more expensive than during the construction phase.

3.2. Operational risks and activity interruptions

Production interruptions: For industrial zones, each hour of machine downtime can cause losses of hundreds of millions of dong. Electrical failures due to overheating often occur suddenly, are difficult to predict, and may take many hours to resolve.

Affected equipment:

- Production machinery stops operating

- Air conditioning and ventilation systems cease functioning

- Office equipment and computers are prone to damage from sudden power loss

- Security systems and surveillance cameras are interrupted

3.3. Serious safety and legal risks

Fire and explosion risks: According to reports from the Fire Prevention, Firefighting and Rescue Department (Ministry of Public Security), during the period from 2012-2020, approximately 60% of fires in civil and industrial buildings originated from electrical systems. Electrical wire overheating is the main initiating factor in these incidents.

Legal liability: According to the Construction Law and guiding circulars, investors, contractors, and consulting engineers all bear legal responsibility if incidents occur due to non-compliance with technical standards.

Possible legal consequences:

- Administrative violation penalties

- Suspension of construction operation licenses

- Criminal prosecution if causing major damage

- Compensation for personal and property damage

3.4. Impact on reputation and business opportunities

Loss of industry reputation: A serious electrical incident can affect a construction unit's reputation for many years. Investors often share information about problematic contractors, affecting the ability to win future project bids.

Increased insurance costs: Insurance companies often increase premiums or refuse to renew contracts with buildings having a history of electrical incidents. This creates long-term financial burden for investors.

4. What to do when electrical wires overheat? Diagnostic and safe handling guidelines

When discovering the phenomenon of electrical wire overheating, proper procedural handling not only ensures safety but also helps accurately identify causes for effective remedial measures. Below is the recommended handling process for engineers and electricians.

4.1. Step 1: Disconnect power supply to ensure safety

Golden rule: Never work on electrical systems with live voltage. This is a mandatory principle in all international electrical safety standards.

Power disconnection sequence:

- Switch off circuit breakers/switches at the main electrical panel

- Verify no voltage using specialized measuring equipment

- Hang “Do not energize” signs and lock the electrical panel

- Notify all relevant personnel

Required personal protective equipment:

- Insulating gloves meeting IEC 60903 standards

- Electrical safety shoes

- Safety glasses against electrical arc

- Fire-resistant clothing

4.2. Step 2: Isolate the incident area and conduct preliminary assessment

Accurately identifying the location and scope of overheating phenomenon helps provide appropriate handling solutions.

Signs to observe:

- Hot location: at connections, plugs, or the entire wire run?

- Severity level: slightly warm or hot enough to cause burns?

- Duration: occurs continuously or only under high load?

- Affected area: one circuit or multiple electrical circuits?

4.3. Step 3: Detailed visual inspection

Carefully observe abnormal signs to accurately determine the main cause.

Insulation inspection:

- Color changes (yellow, brown, black)

- Cracked or deformed surfaces

- Characteristic burnt plastic odor

- Burn marks or black spots at contact points

Connection and plug inspection:

- Signs of oxidation (green color on red copper)

- Loose connections

- Abnormally high temperature at contact points

4.4. Step 4: Professional technical measurements

Use specialized measuring equipment to accurately determine system condition.

Required measurements:

- Clamp meter: Measure actual current compared to rated current

- Megger: Accurately measure insulation resistance

- Infrared thermometer: Determine temperature distribution

Standard parameters for comparison:

- Current must not exceed 80% of wire rating

- Minimum insulation resistance of 1MΩ/kV rated voltage

- Surface temperature must not exceed material limits

4.5. Step 5: Determine remedial solutions

Based on inspection results, provide appropriate handling measures for each specific cause.

- Overload: Reduce load or increase wire cross-sectional area

- Loose connections: Tighten and apply anti-oxidation paste

- Poor quality wire: Replace with standard-compliant wire

- Damaged insulation: Replace entire affected wire section

4.6. Inspection and acceptance after repairs

After remediation, strict inspection procedures must be performed before putting into use.

- Measure and check technical parameters

- Gradual load testing from 25%, 50%, 75% to 100%

- Monitor temperature for 2-4 hours

- Prepare technical report and handover

5. How to completely prevent electrical wire overheating from the beginning?

Preventing the phenomenon of electrical wire overheating is the most economical and effective solution, helping to avoid unwanted risks and costs. Properly applying technical standards from the design and construction phases creates an electrical system that operates safely and stably.

5.1. Understanding and correctly applying TCVN & IEC standards

Strict compliance with standards helps ensure safety for people and property, improving equipment durability and efficiency. Basic standards to master include:

- TCVN 6610 / IEC 60227: Regulations for polyvinyl chloride insulated cables with rated voltage up to and including 450/750V

- TCVN 5935-1 / IEC 60502-1: Regulations for power cables with extruded insulation and their accessories for rated voltages from 1kV to 30kV

- TCVN 6612 / IEC 60228: Regulations for conductors of insulated cables

5.2. Accurate calculation and selection of conductor cross-sectional area

Choosing the correct conductor cross-sectional area is the most important factor in electrical system design. Calculations must be based on multiple factors, not just load power alone.

Basic calculation formula: S = I / J

- S: Conductor cross-sectional area (mm²)

- I: Rated current (A)

- J: Permissible current density of the conductor (A/mm²)

5.3. Why choose pure red copper conductors and XLPE insulation?

Material quality is the determining factor for electrical system durability and efficiency. Ngoc Lan Cable always recommends using pure red copper conductors and XLPE insulation for projects requiring high performance.

Advantages of red copper conductors:

- Best electrical conductivity among common metals

- Natural oxidation resistance in normal environments

- Easy processing, connection, and maintenance

- High lifespan with minimal maintenance

Advantages of XLPE:

- Ability to withstand heat without deformation at extremely high or low temperatures for extended periods

- High insulation resistance, increasing safety and minimizing electrical leakage risks

- Water resistance and good impact resistance

- Resistance to corrosion from various chemicals and alkaline corrosives

5.4. Proper construction and installation procedures

Even when using high-quality materials, improper construction techniques can still cause overheating phenomena.

Construction principles to follow according to TCVN 9207:

- Minimum bending radius: 6 times the cable's outer diameter

- Distance between conductors must not be less than 100mm when fixed spacing is up to 6m, and not less than 150mm when fixed spacing exceeds 6m

Construction inspection checklist:

- Connections made with proper technique and adequate torque

- Use anti-oxidation paste for red copper connections

- Protect wires from sharp edges and friction

- Create ventilation for heat dissipation in cable routing areas

5.5. Installing protective and monitoring equipment

Modern protection systems not only disconnect power during faults but also provide early warning of abnormal signs.

Essential protective equipment:

- MCB (Miniature Circuit Breaker): Overload and short-circuit protection

- RCD (Residual Current Device): Electrical leakage protection

- RCBO (Residual Current Breaker with Overcurrent): Combines both functions above

- Electronic thermal relay: Temperature monitoring and high-temperature warning

Investing in intelligent monitoring systems helps detect abnormal signs early, enabling timely corrective measures before serious incidents occur.

6. Frequently asked questions about electrical wire overheating

6.1. At what temperature is warm electrical wire considered normal?

PVC wires are safe when surface temperature is below 60°C, XLPE wires below 80°C. Exceeding these levels or detecting burning odors are dangerous signs requiring immediate attention.

6.2. Why are poor-quality wires prone to overheating?

Poor-quality wires have higher resistance, generate more heat, and reduce system lifespan.

6.3. Are loose connections dangerous?

Extremely dangerous. Loose connections increase contact resistance, leading to heat generation at connection points, melting insulation, and potentially causing fires and explosions. They must be tightened and inspected regularly.

6.4. How dangerous is electrical overloading?

Overloading causes rapid temperature increases, ages the insulation layer, and reduces wire lifespan. The risk of fire and explosion is very high.

7. Summary of solutions to prevent electrical wire overheating

The phenomenon of electrical wire overheating can be completely prevented through proper application of technical standards and selection of quality materials. The above analysis has clearly identified seven main causes of overheating, from incorrect conductor cross-sectional area calculations and use of poor-quality materials, to errors in construction and maintenance.

Key points to remember:

- Electrical safety originates from proper design and standard-compliant material selection

- Compliance with TCVN/IEC standards helps prevent 95% of thermal incidents

- Investing in material quality saves long-term operating costs

- Regular inspection procedures help detect early warning signs

When electrical wire overheating is detected, the safe handling process consists of five basic steps: disconnecting power supply, isolating the incident area, visual inspection, professional technical measurements, and applying appropriate remedial solutions. Strict adherence to these steps not only avoids risks to people and property but also accurately identifies causes for long-term corrective measures.

Do you need professional consultation on safe electrical systems for your project? Ngoc Lan Cable with experience in manufacturing according to TCVN and IEC standards will support calculations, select suitable products, and accompany you in building reliable electrical systems for your construction projects.

VN

VN